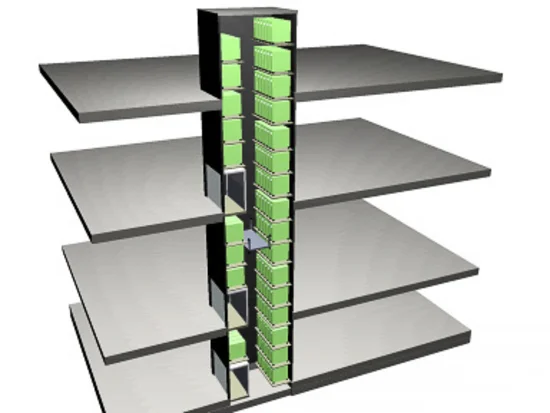

Compact vertical storage for trolleys and bins

The Lödige Space Tower is a high-bay storage and vertical transport solution for catering trolleys and bins. It combines storage and conveying functions in one compact system, ensuring hygienic, safe and transparent catering logistics. Designed for maximum space efficiency, it can reach heights of up to 22–30 m and handle up to 170 trolleys or 540 bins in a single tower.

Seamless flows with full transparency

The Space Tower provides a central storage and retrieval system for inbound and outbound catering flows. It safeguards the cold chain, supports ergonomic handling, and enables fast access to trolleys and bins. Barcode or RFID identification and integrated inventory management ensure real-time transparency and accurate stock control.

The tower can operate in ambient, chilled or frozen environments, meeting international hygiene and food safety standards. By eliminating manual floor transfers and stock in transit, the system reduces costs and creates lean, efficient processes.

Benefits of Lödige’s SpaceTower

Designed for modern catering operations, our solutions deliver measurable benefits by improving efficiency, ensuring hygiene and supporting seamless process integration.

Proven Features & Options

The Space Tower offers a range of proven features and options to adapt perfectly to your catering process and facility layout.

Features & Options

- Layout and Capacity

Single or twin-tower configuration with adaptable height and tray levels for trolleys or catering units. - Temperature Control

Available for ambient, chilled or frozen storage with fully insulated panels and energy-efficient cooling units. - Loading Interfaces

Manual or fully automated connection to conveyors, lifts or washing areas. - Control and Software

Integrated warehouse management with tray tracking, automatic inventory control and touchscreen operation. - Hygiene and Safety

Stainless-steel design, access monitoring and secure maintenance platforms for easy cleaning and safe operation.

Technical Data

Trolley Tower | Bin Tower | |

| Max. platform capacity | 750 kg | 250 kg |

| Max. trolleys/bins | 250 | 1,000 |

| Ambient/temperature control | Ambient or temperature controlled storage of trolleys | Ambient or temperature controlled storage of bins/baskets |

| Operator comfort | Storage platform presented flush with floor | Opening platform with clearance for bins of different heights |

| Design | Available for different trolley heights | Ergonomic design; storage platform presented at ergonomic height |

| Hygiene requirements | Meets hygiene requirements | Meets hygiene requirements |

| Access | Barcode or RFID identification, inventory management | Barcode or RFID identification, inventory management |

Automation Degree

The Space Tower is available in different automation levels. In its basic version, it can be operated as a stand-alone system with manual infeed and outfeed. As requirements grow, the Bin Tower can be upgraded to a fully automated solution with integrated conveyor systems, enabling seamless connections to tray setting, cleaning and outbound loading areas. This scalability makes the Space Tower suitable for both medium-sized and mega catering hubs.

Tools & Downloads

-

Soluții logistice pentru aeroporturi

Broșură (engleză) -

Servicii de catering, Cathay Pacific din Hong Kong

Pliant (disponibil doar în chineza simplificată)

Available for Trolleys and Bins

The Space Tower can be configured for both catering trolleys and bins, providing efficient, space-saving storage and seamless integration into your catering logistics process.

Fully automated catering logistics for Cathay Dining (formerly known as CPCS), Hong Kong

At Cathay Dining in Hong Kong, Lödige implemented a fully automated material flow system including Space Towers, bin and pallet conveyors, and an integrated warehouse management system.

Efficient Solutions for Modern Catering Logistics

From cleaning to loading – Lödige systems ensure hygienic, space-saving and reliable catering flows.

Explore the complete range of Lödige catering logistics solutions – from trolley and bin handling to automated storage and conveying systems.

Lödige conveyor and handling systems connect cleaning, tray setting, storage and outbound areas in one continuous, hygienic flow. Scalable from manual to fully automated operation, they ensure smooth and reliable catering logistics.

Unlock new levels of efficiency in your catering operations.

Contact us to design your Space Tower system – scalable, hygienic, and built for 24/7 performance.

Frequently Asked Questions (FAQs)

Depending on configuration, a single tower can store up to 250 trolleys or 1,000 bins.

Yes. Versions are available for either trolleys or bins, and both can be integrated into the same facility.

Yes. It can be installed for ambient, chilled or frozen environments.

Yes. It can be installed as a stand-alone system or connected to automated conveyor systems for a fully integrated solution.

Barcode or RFID identification combined with a database system ensures fast, reliable and transparent access to all stored items.