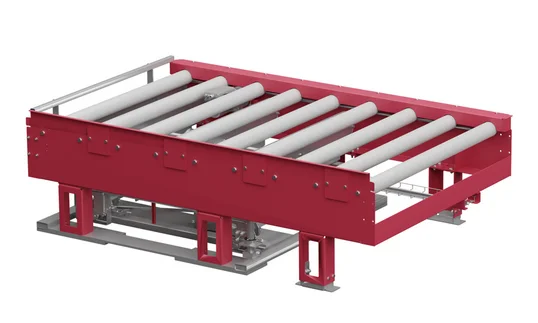

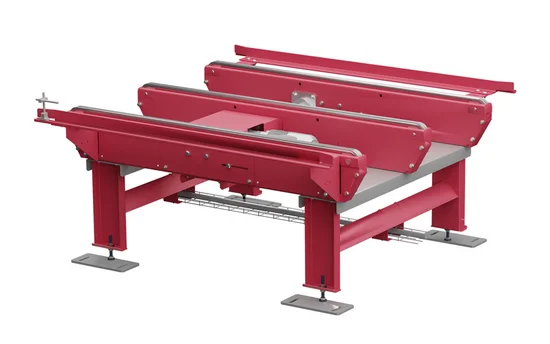

Chain Conveyor

Move your in-house pallets safely and efficiently across your cargo terminal

Optimise the internal transport of consignments within your terminal using Lödige's robust Chain Conveyors. These modular systems ensure smooth, reliable movement of in-house pallets (IHP), reducing manual handling, enhancing cargo safety, and significantly increasing throughput.

Reliable cargo transport with modular flexibility

Lödige Chain Conveyors offer a modular and scalable solution for transporting in-house pallets (IHP) within Automated Storage and Retrieval Systems (ASRS) at air cargo terminals. Designed specifically to handle repetitive internal transport along predefined routes, these conveyors seamlessly integrate with stacker cranes, hoists, and racking systems. Their robust construction and chain-driven design ensure efficient and gentle handling of your cargo, while easy customisation in length, height, and layout supports flexible adaptation to evolving operational requirements.

Benefits of Lödige’s Chain Conveyor

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Application – Built for Air Cargo Storage and ASRS Systems

Chain conveyors are essential for air cargo terminals that rely on ASRS and consignment storage. They connect horizontal transport routes between pallet in-feed/out-feed, stacker cranes, and racking systems. Particularly suited for longer distances or heavier loads, they complement roller conveyors perfectly within high-throughput automated cargo terminals.

Features / Options

- Integration with Right Angle and Roller Conveyors

- Safety features (emergency stops, overload protection)

- Chain tensioning systems for smooth operation

- Integrated scale

- In- and Out Feed Lanes to ASRS with following features:

Pallet overweight detection, Contour check, Bar code identification, Pallet guides, Camera for taking pictures of pallet on deck, Large Text Display

Technical Data

Description | |

|---|---|

| Capacity | 1300 kg |

| Length | 1,750 mm |

| Width | The Inhouse Pallets are available in three distinct sizes (1,000 - 1,700 mm), selected based on the specific cargo profile requirements. Systems can be precisely tailored to these dimensions to optimise operational efficiency and compatibility. |

| Transfer Height | 1,000 / 1,040 mm |

Automation Degree

Chain conveyors offer a high automation level by enabling fully automated pallet transfers within ASRS and storage systems. They reduce manual handling, handle misaligned loads, and ensure reliable, continuous cargo flow—essential for scalable, efficient terminal operations.

Tools & Downloads

-

Airport Logistics Solutions

Brochure

Chain conveyor successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

At the ‘Cool Nordic Cargo Hub’ of Finnair at Helsinki Airport, Lödige delivered a complete cargo handling solution. Within the consignment storage, chain conveyors ensure reliable horizontal pallet transfer, seamlessly connecting stacker cranes, hoists and racking.

At the Istanbul Mega Hub of Turkish Cargo, Lödige delivered a complete cargo terminal solution. Within the consignment storage, chain conveyors provide efficient horizontal pallet transfer, ensuring smooth integration of cranes, hoists and racking.

Related Products

Discover Solutions for Consignment Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Let's plan your new consignment storage or modernise your existing one.

Speak to our experts. They will define your optimal solution.

FAQs

Yes. Chain conveyors are designed for seamless integration with ASRS, stacker cranes, and pallet storage racking in air cargo terminals.

Depending on the configuration, each pallet has a payload of up to 1300 kg.

Yes, they operate reliably in temperatures from -30°C to +60°C, ideal for temperature-sensitive goods.

It links horizontal transport to stacker cranes, ASRS racking, and forklift in-feed and out-feed areas, ensuring a seamless flow of in-house pallets.

Typical speeds are tailored to the terminal design but generally match standard ASRS speeds for horizontal pallet movement, with gentle acceleration to protect cargo.

Yes, the drive motor can be disengaged via a clutch, allowing manual movement of pallets.

Chain conveyors are better suited for long distances, heavier loads, and situations where precise pallet alignment is critical.

Absolutely. Thanks to its modular design, the chain conveyor can be expanded or reconfigured as storage demands grow.

Yes. Chain conveyors are successfully used in major international air cargo hubs as part of fully automated consignment storage and ASRS environments. (Reference: e. g. Finnair, Turkish Cargo)

By connecting key functional areas like stacker cranes, in-feed/out-feed conveyors, and racking, it eliminates manual handling steps and optimizes throughput.

Common applications include linking ASRS storage levels, consignment storage, and automated build & break zones in air cargo terminals.