OPTIMUM FLOW OF GOODS IN EVERY DIRECTION

Today‘s automobile industry expects maximum speed, precision and efficiency in every area.

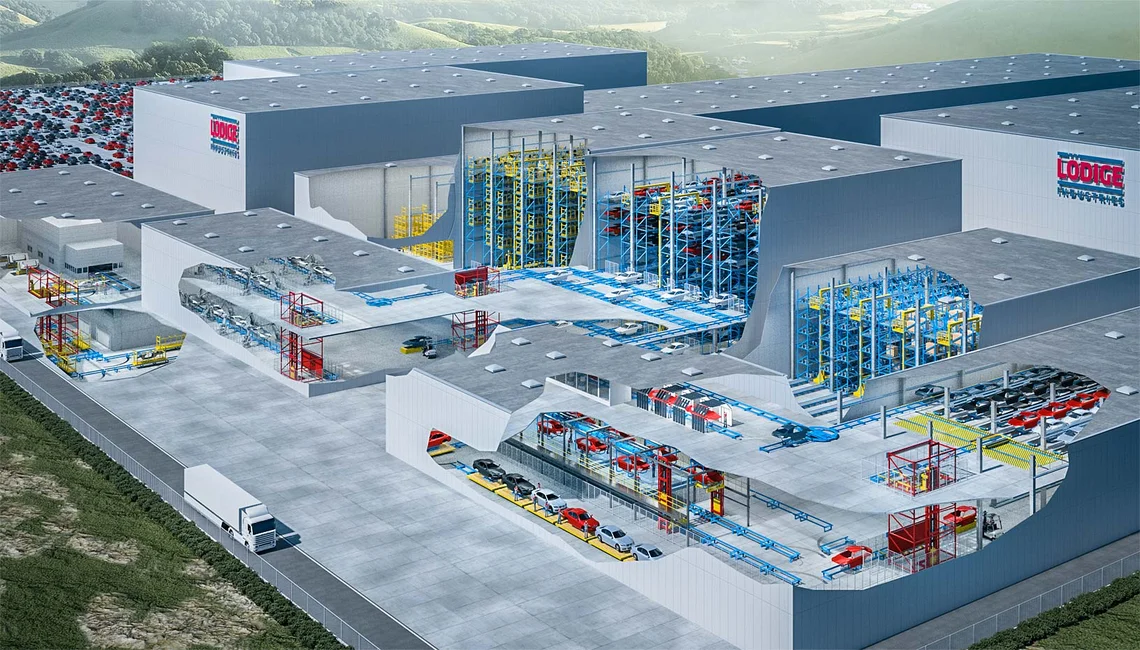

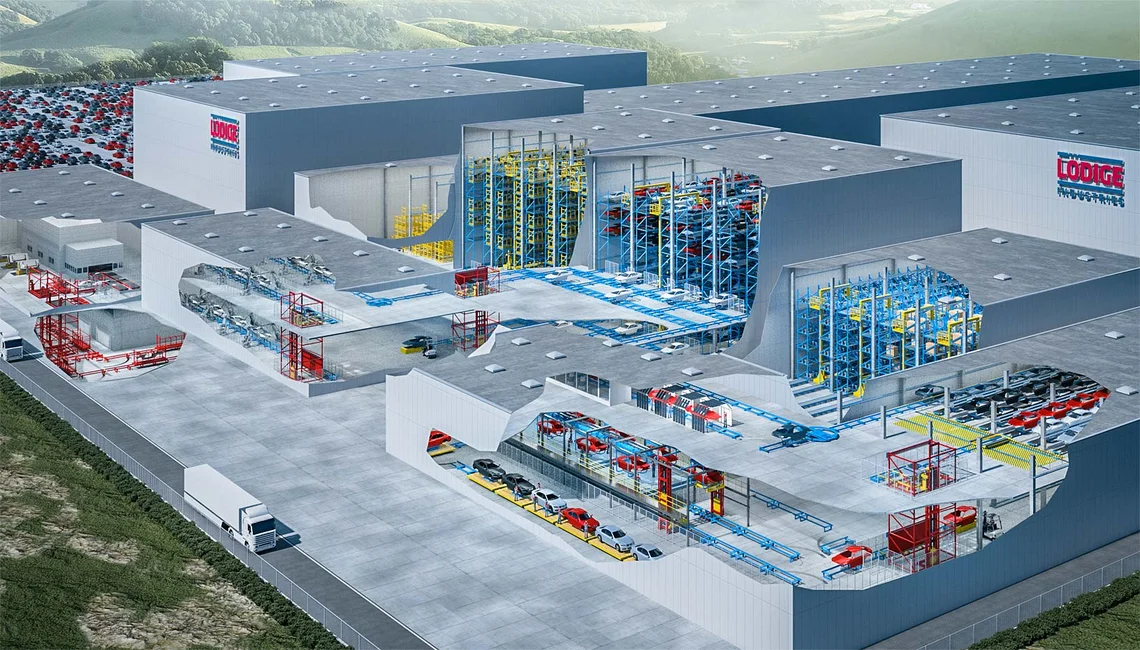

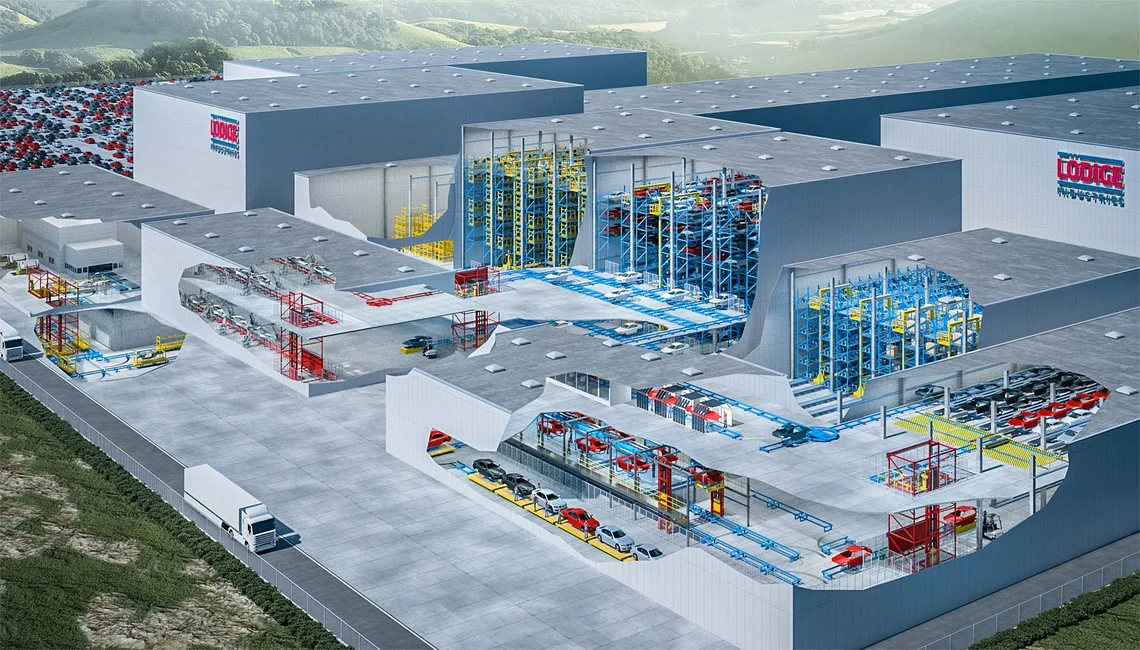

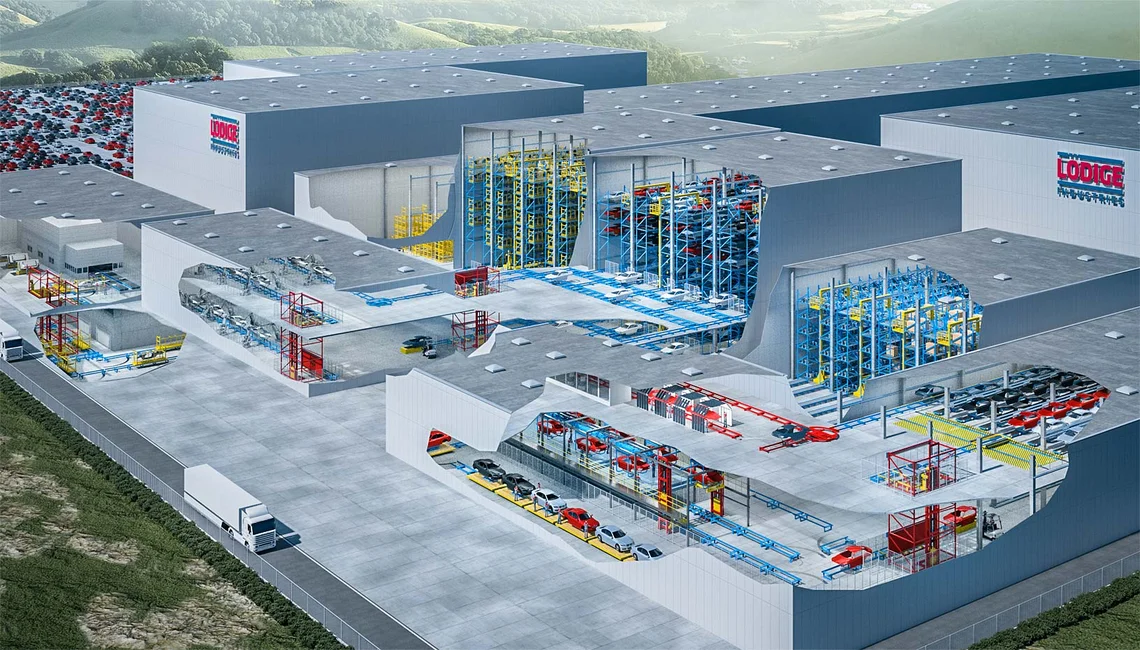

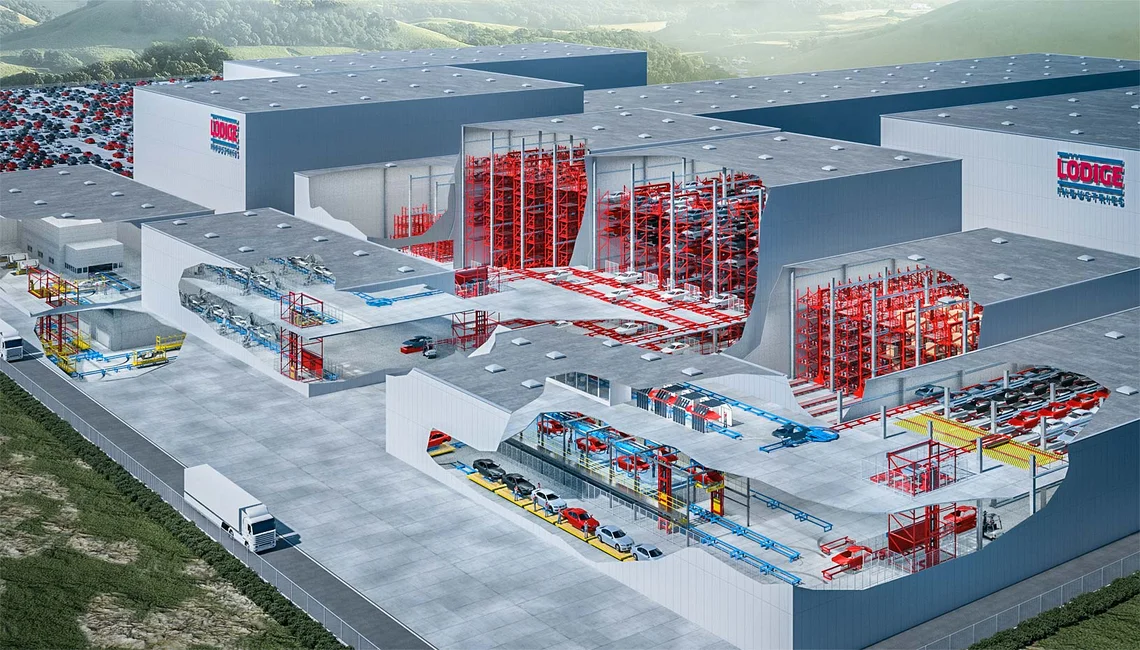

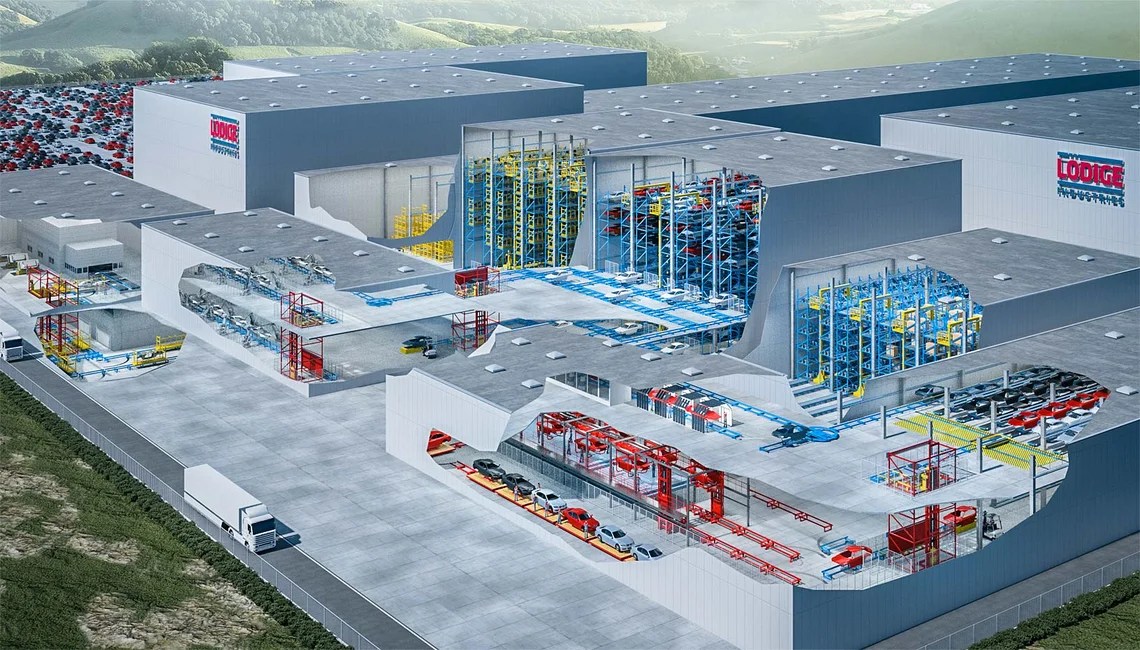

Manufacturing processes in the automobile industry make particularly high demands on intralogistics. From raw material supply to final assembly of cars, all the necessary components must reach their point of use safely and ready for use. Ensuring materials handling solutions work in perfect harmony, including between individual work areas, requires a partner who can provide solutions for the whole production process. Lödige Industries is just this partner.

From high-bay warehousing for pressed components, bodywork, engines and gearboxes, through every type of materials handling system, to control engineering, we supply the solutions from a single source. The Lödige portfolio covers every requirement in vehicle production.

We make sure that our automation and software controls suit your production and warehousing processes – just-in-time and just-in-sequence. Exact workflows, centrally monitorable processes and high throughput are the hallmark of our automation processes. Find out how we can support your project.

Automobile industry solutions portfolio

Find out more about Lödige Production Logistics

-

Production Logistics

Overview of the production logistics portfolio -

Production Logistics for the Automobile Industry

Brochure