OPTIMUM FLOW OF GOODS IN EVERY DIRECTION

Today‘s automobile industry expects maximum speed, precision and efficiency in every area.

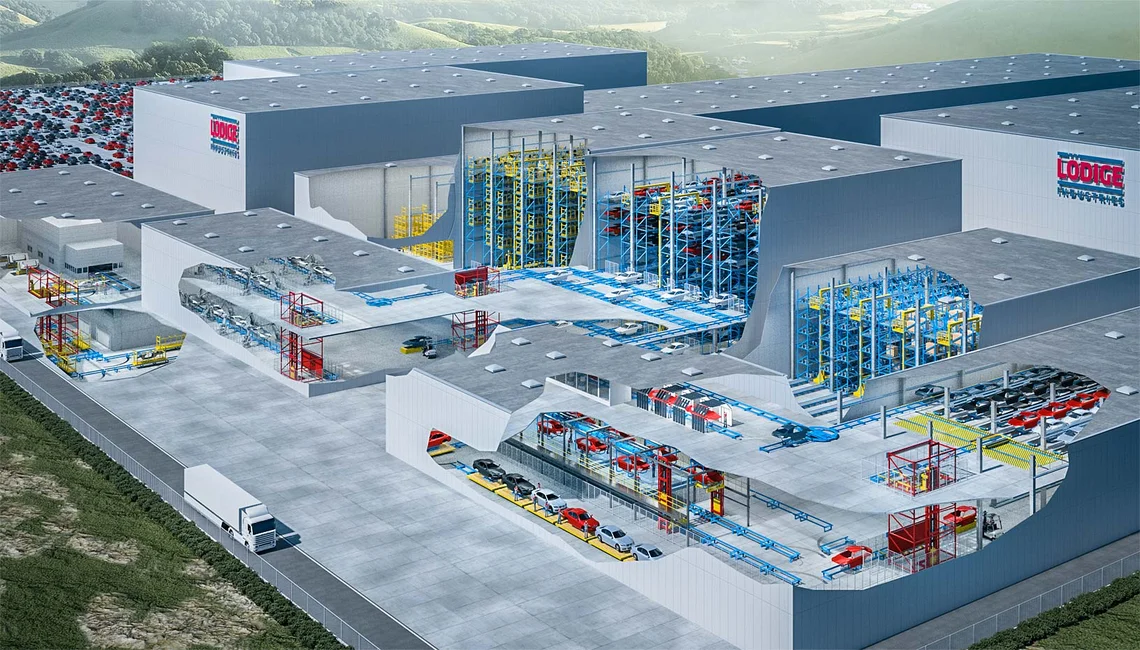

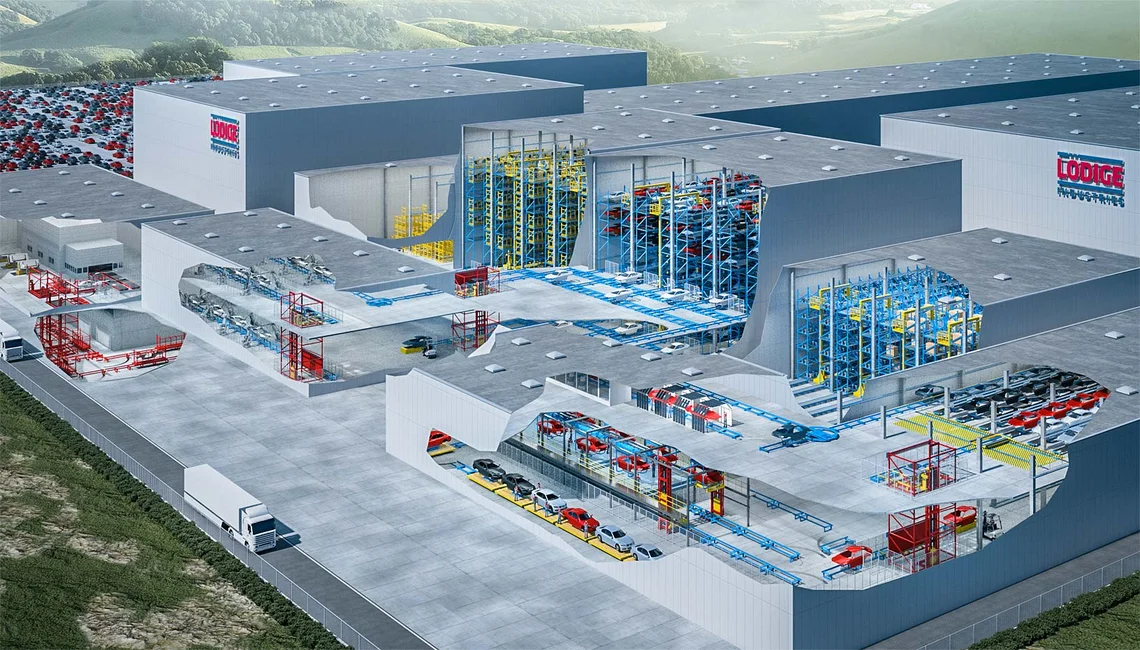

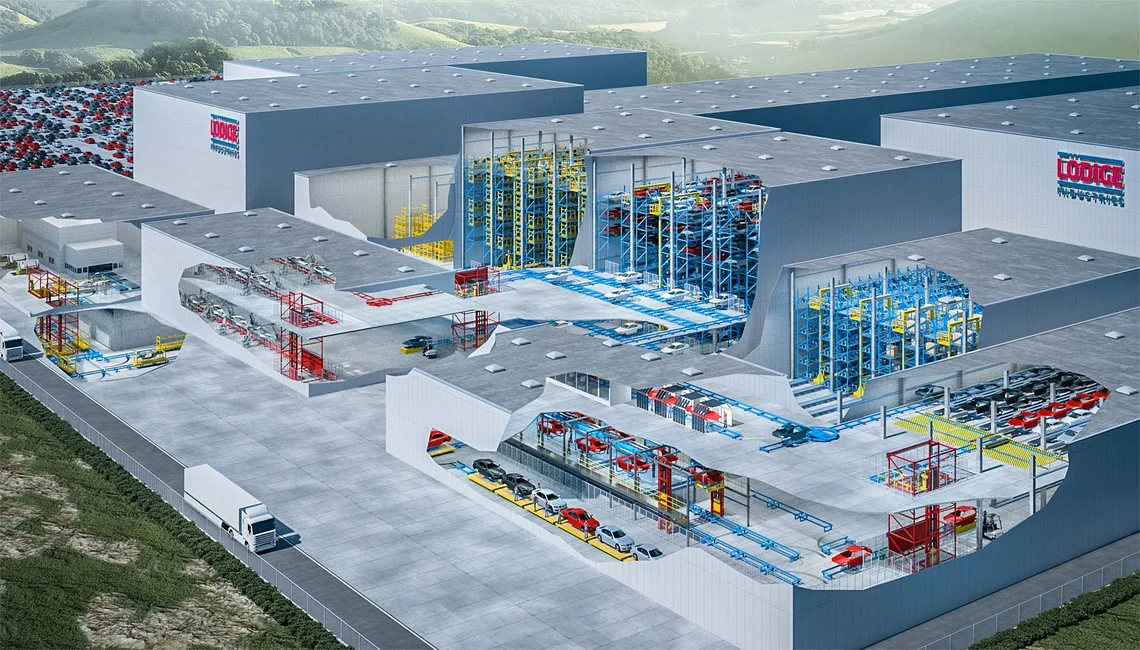

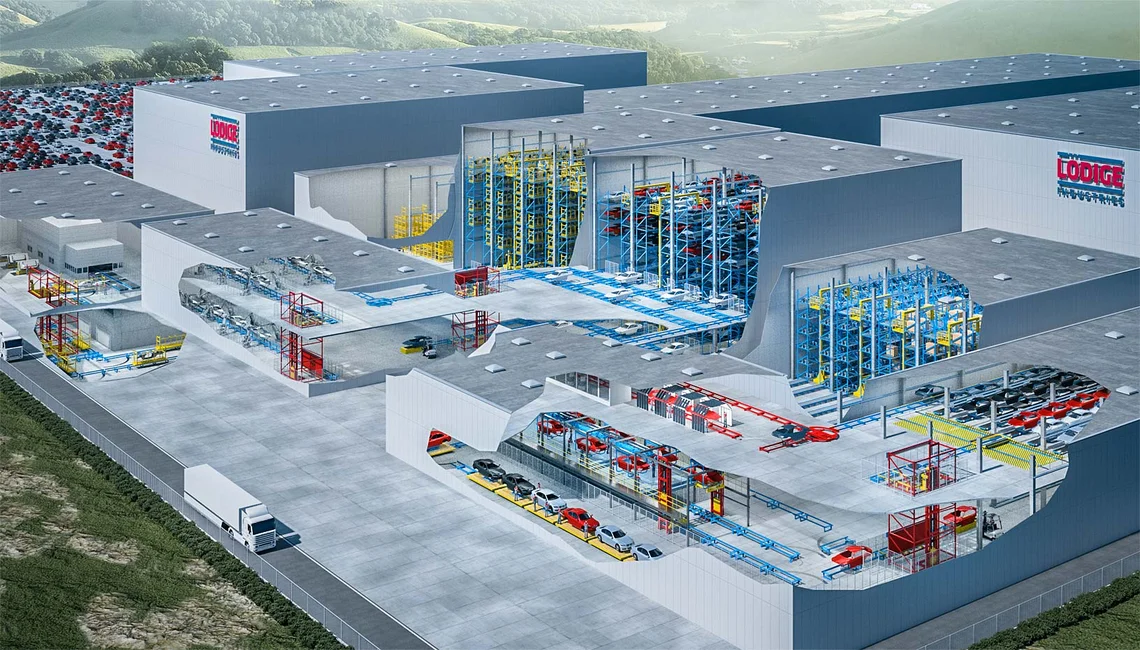

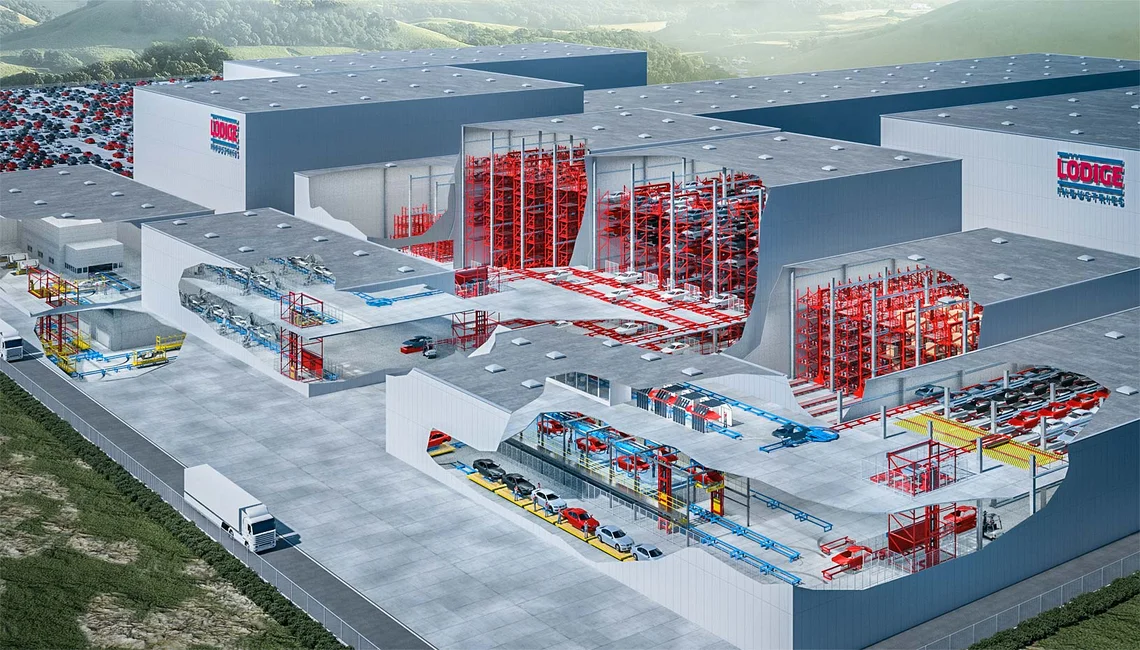

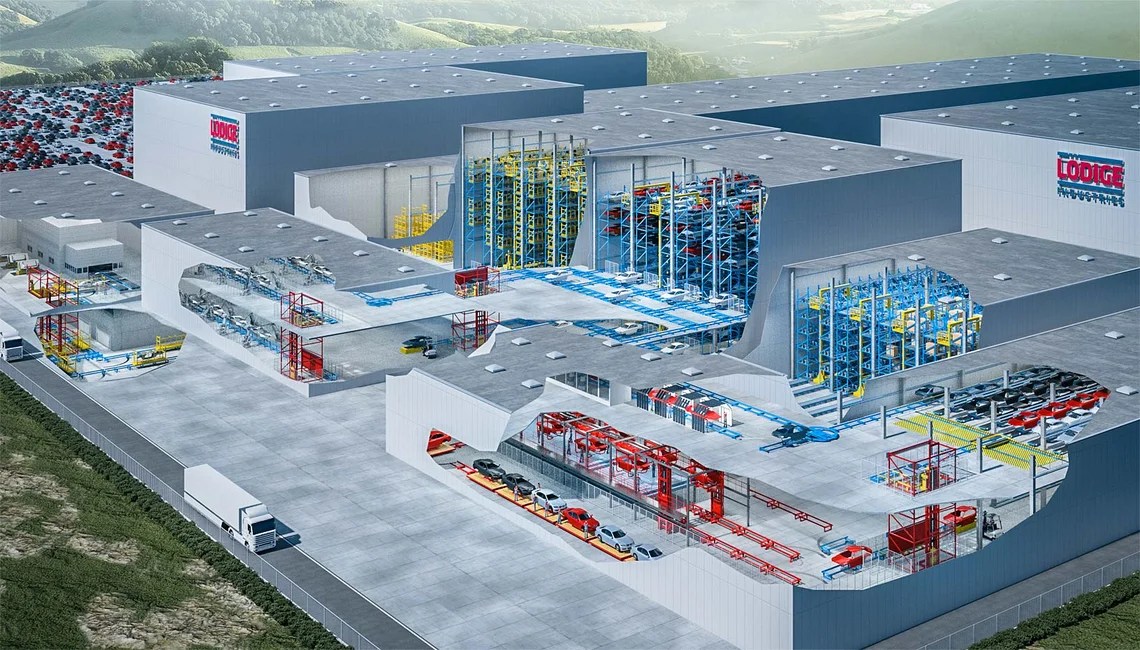

Manufacturing processes in the automobile industry make particularly high demands on intralogistics. From raw material supply to final assembly of cars, all the necessary components must reach their point of use safely and ready for use. Ensuring materials handling solutions work in perfect harmony, including between individual work areas, requires a partner who can provide solutions for the whole production process. Lödige Industries is just this partner.

From high-bay warehousing for pressed components, bodywork, engines and gearboxes, through every type of materials handling system, to control engineering, we supply the solutions from a single source. The Lödige portfolio covers every requirement in vehicle production.

We make sure that our automation and software controls suit your production and warehousing processes – just-in-time and just-in-sequence. Exact workflows, centrally monitorable processes and high throughput are the hallmark of our automation processes. Find out how we can support your project.

Automobile industry solutions portfolio

Find out more about Lödige Production Logistics

-

Production Logistics

Overview of the production logistics portfolio -

Production Logistics for the Automobile Industry

Brochure

Automobile Industry Frequently Asked Questions (FAQs)

Automotive logistics is the intricate and crucial process of efficiently moving vehicles and parts across the global supply chain. It involves activities like transportation, warehousing, inventory management, and customer service.

This complex network integrates suppliers, manufacturers, distributors, and customers through advanced technologies and information flows.

In recent years, the automotive industry's challenges, such as the rise of electric vehicles and customisation demands, have necessitated a responsive and adaptable logistics system.

Just some of the benefits of using our automotive industry solutions include:

- Speed, Precision, and Efficiency: Lödige Industries focuses on delivering maximum speed, precision, and efficiency in every aspect of automotive manufacturing. Comprehensive Materials Handling Solutions: We provide a complete set of materials handling solutions that work seamlessly across different stages of automotive manufacturing. This includes high-bay warehousing for various components such as pressed parts, bodywork, engines, and gearboxes.

- Single-Source Supplier: Lödige Industries serves as a single-source supplier for automotive industry solutions. This means that we offer a comprehensive range of solutions, from high-bay warehousing to materials handling systems and control engineering, simplifying the procurement process for automotive manufacturers.

- Customised Solutions for the Entire Production Process: The solutions provided by Lödige Industries are tailored to meet the unique requirements of the entire production process in the automotive industry. This includes addressing the challenges associated with the movement of materials between individual work areas.

- Automation and Software Controls: We ensure that automation and software controls are aligned with the specific needs of automotive production and warehousing processes. This enables just-in-time and just-in-sequence deliveries, contributing to precise workflows, centralised monitoring, and high throughput.

- Centrally Monitorable Processes: The automation processes implemented by Lödige Industries are designed to be centrally monitorable. This feature allows for real-time tracking and management of workflows, enhancing overall process visibility and control.

At Lödige Industries, we understand the dynamic demands of the automotive industry. From seamlessly managing the intricate flow of raw materials through high-bay warehousing to providing comprehensive materials handling systems, our offerings are tailored to meet your unique challenges. We take pride in being a single-source supplier, delivering not just solutions, but a holistic approach to optimise your entire manufacturing workflow. Our commitment extends to customising automation and software controls, ensuring just-in-time and just-in-sequence operations for heightened efficiency.

Operating Lödige Industries' automotive industry solutions is designed to seamlessly integrate without disrupting your ongoing operations. Our systems come with intuitive interfaces to facilitate easy use, and we pride ourselves on a track record of successful installations that do not interrupt daily activities.