CARGO CONTROL

Part of Cargo Professional Suite

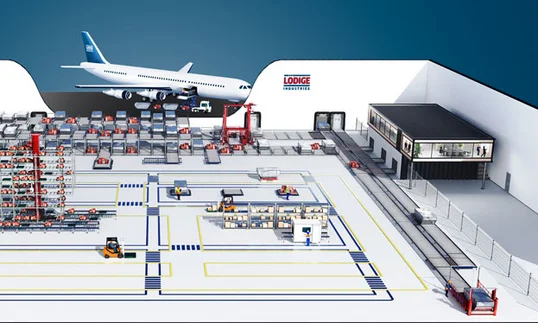

Managing Unit Load Devices (ULDs) and in-house pallets reliably is essential for smooth cargo handling. Cargo Control is the core module of the Cargo Professional Suite – designed to track every movement, steer equipment and ensure seamless flow across your terminal.

Central Command for ULDs and IHPs

Cargo Control manages ULDs and in-house pallets (IHPs) across all handling processes. It monitors equipment in real time, controls storage and transport flows, and makes every movement transparent and reliable. By coordinating manual, semi-automated and fully automated systems, it ensures consistent throughput and dependable process control.

Benefits of Lödige’s Cargo CONTROL

Our software solutions empower terminals with greater visibility, reliable process automation and seamless integration across all cargo flows.

Modular Software

CARGO CONTROL is the core system for managing ULDs and in-house pallets. The following software modules ensure reliable transport, storage and handling across all levels of automation.

Equipment Diagnostic System (EDS)

Provides condition-based monitoring of drives, conveyors and vehicles. Supports remote resets, tracks recurring faults and enables preventive maintenance. Increases system uptime and reduces operational risks.

For all processes

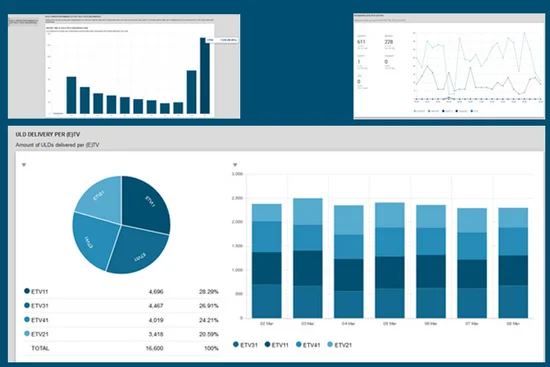

MIS – Report Analytics (Light Version)

Provides historical reporting and analysis tools. Identifies peak hours, tracks SLA performance and highlights compliance gaps. Helps terminals plan resources and continuously improve efficiency.

Cargo Control software module “MIS - Report Analytics (Light Version)” supports these processes:

Landside Interface ULD-Storage

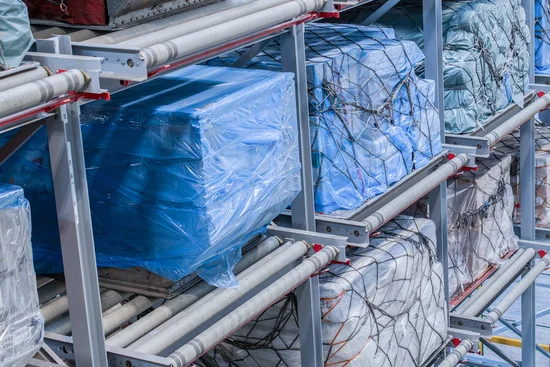

Pallet Control System (PCS)

Handles all in-house pallets, from barcode identification to X-ray integration and storage optimisation. Ensures compliance, transparent tracking and smooth connections between landside acceptance and automated storage.

Cargo Control software module “Pallet Control System” supports these processes:

Landside Interface Consignment Storage

Intra Terminal Transport

ULD Control System (UCS)

Manages every ULD in the terminal with real-time tracking. Functions include identification, contour check, weighing, storage optimisation and workstation presentation. Ensures SLA compliance and smooth ULD flows across storage and airside operations.

Cargo Control software module “ULD Control System” supports these processes:

Landside Interface Build & Break Intra Terminal Transport ULD Storage Airside Interface

AGV Fleet Management

Manages AGV operations across the terminal, coordinating multiple vehicles simultaneously. Optimises routing, prevents congestion and ensures reliable handover between zones. Reduces manual intervention and supports scalable, flexible transport capacity.

The software module “AGV Fleet Management” supports these processes:

Intra Terminal Transport Build & Break

Forklift Guidance System (FLGS)

Coordinates and sequences all build-up and breakdown jobs. Assigns tasks dynamically to workstations, ensuring balanced workload and adherence to flight schedules. Improves reliability and on-time performance during peak periods.

Cargo Control software module “Forklift Guidance System” supports these processes:

Intra Terminal Transport Build & Break

Consignment Storage ULD Storage

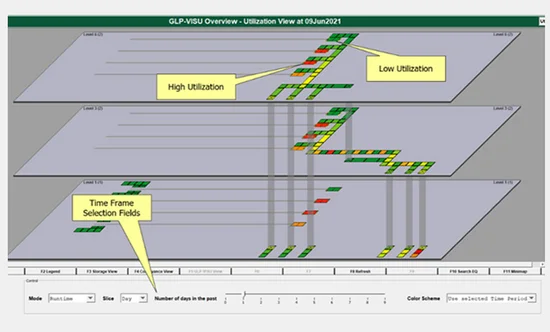

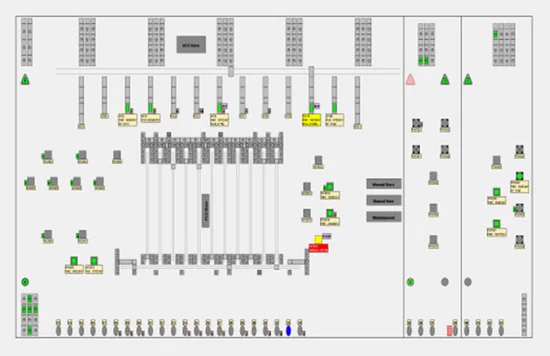

Live Operation Displays

Gives operators a real-time overview of cargo movements, job progress and system utilisation. Improves coordination between manual and automated processes and provides transparency for shift planning.

Cargo Control software module “Live Operation Display” supports these processes:

Auto Breakdown

Automates ULD breakdown. Inbound ULDs are scanned and systematically unpacked, with freight directed to the correct storage, workstation or outbound process. Improves throughput and reduces manual handling errors.

Cargo Control software module “Auto Breakdown” supports this process:

Build & Break

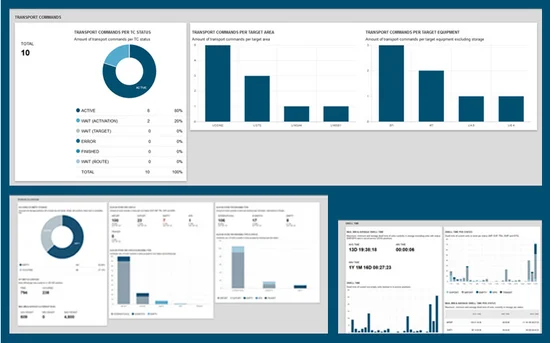

MIS – Live Analytics (Light Version)

Delivers real-time dashboards for monitoring equipment status, job queues and cargo movements. Enables operators to react instantly to bottlenecks or delays, ensuring uninterrupted flows.

Cargo Control software module “MIS - Live Analytics (Light Version)” supports these processes:

Cargo Professional successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

At Finnair Cargo’s COOL terminal in Helsinki, Lödige’s Cargo Professional Suite ensures seamless management of ULD and inhouse pallet flows. The system provides real-time transparency, reliable compliance checks and efficient coordination of cargo processes – supporting one of Europe’s most modern air cargo facilities.

At Turkish Cargo’s state-of-the-art terminal in Istanbul, Lödige’s Cargo Professional Suite manages high volumes of ULDs and inhouse pallets with precision and speed. The system ensures smooth cargo flows, real-time transparency and reliable integration into the terminal’s processes – supporting one of the world’s busiest air cargo hubs.

Discover the Software Behind Efficient Cargo Handling

Two powerful modules – one integrated platform. The Cargo Professional Suite connects Cargo Control and Cargo Direct for complete visibility and reliable performance in your terminal.

Unite all cargo flows in one platform. The Cargo Professional Suite integrates every process from landside to airside, providing full visibility and automation potential for terminals of any size.

Gain shipment-level transparency with Cargo Direct. By integrating e-AWB data and process automation, it ensures consistent, efficient and compliant handling across all processes.

Navigate through the processes in the cargo terminal

Ready to transform your terminal?

Discover how the Cargo Professional Suite can boost efficiency, transparency and control.

Frequently Asked Questions (FAQs)

Cargo Control is one of the two core modules of the Cargo Professional Suite. It focuses on ULDs and in-house pallets, managing equipment flows and storage in real time. By ensuring every movement is transparent and reliable, it forms the backbone for efficient cargo handling. Together with Cargo Direct, it provides end-to-end visibility and process control across the terminal.

Key modules include ULD Control System (UCS), Pallet Control System (PCS), Forklift Guidance System (FLGS), Manual Store Administration (MSA), Equipment Diagnostic System (EDS), AGV Fleet Management and Live Operation Displays.

By tracking forklifts, pallet movers and AGVs in real time, it prevents congestion and reduces manual errors. Integrated diagnostic tools increase safety and reduce downtime.

Cargo Control manages ULD and inhouse pallet flows across the terminal. Cargo Direct ensures shipment-level transparency inside ULDs and pallets. Both can be used individually or together.

Yes. It supports manual, semi-automated and fully automated systems. Even in manual operations, Cargo Control provides visibility and process reliability.

The Cargo Professional Suite supports IATA and Cargo iQ standards, integrates compliance checks and ensures complete traceability of cargo flows.