Storage Decks – Reliable ULD Storage and Buffering for Cargo Terminals

Efficient ULD storage for seamless cargo handling

Storage Decks enable safe and efficient storage, buffering, and positioning of ULDs within air cargo terminals. As core components of storage systems, they ensure smooth cargo flow between landside, internal processes, and airside operations.

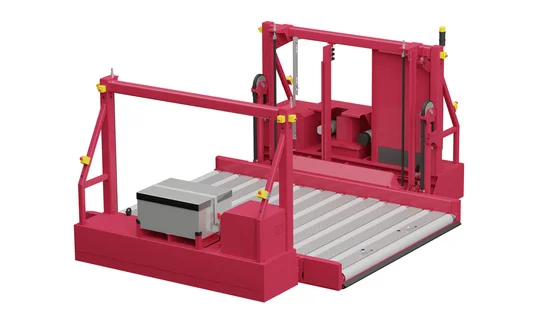

Storage Deck for Air Cargo Terminals

Lödige Storage Decks are friction-powered, modular roller decks designed for storing and buffering ULDs in single or multi-level racking systems. Built for durability and long service life, the decks feature sealed, heavy-duty ball bearings and robust bolted frames. Side guides with flared ends ensure IATA-compliant positioning. Storage Decks are ideal for holding both loaded and empty ULDs until needed in Build & Break areas, airside transfer, or landside operations.

Benefits of Lödige’s Storage Deck

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Storage Deck comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- Non-powered decks

- Driven by friction wheels on the TV or ETV

- 5 ft

10 ft NEP and WEP

Technical Data

Description | 5ft | 10ft NEP | 10ft WEP |

| Capacity | 1,600 kg | 6,800 kg | 6,800 kg |

| Length | 2,500 mm | 3,600 mm | 2,700 mm |

| Width | 1,800 mm | 2,700 mm | 3,470 mm |

| Conveying speed (friction powered) | 0.3 m/s | ||

Automation Degree

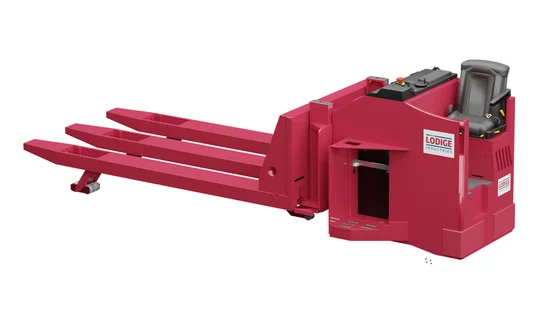

Lödige Storage Decks provide a robust, low-maintenance solution for storing ULDs in automated racking systems. Designed without integrated drives, they enable smooth handover via systems such as ETVs or AGVs. Integrated into a warehouse management system (WMS), they support fully automated, data-driven cargo storage and retrieval.

Tools & Downloads

-

Air Cargo Terminal Equipment

Brochure, (07-2025)

Storage Decks successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

To support Finnair Cargo’s fully automated terminal operations, Storage Decks from Lödige play a key role in the high-bay warehouse of one of Europe’s most advanced air cargo hubs.

At Asia Airfreight Terminal in Hong Kong, Lödige Storage Decks are part of a fully automated high-bay system, supporting the efficient handling of over one million tonnes of cargo per year.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

FAQs

Storage Decks are used to temporarily store or buffer ULDs within racking systems. They are typically integrated into automated or semi-automated ULD storage solutions and ensure that ULDs are safely positioned for retrieval, transfer, or further processing.

No, Storage Decks are friction-powered and do not have integrated drives. ULDs are moved onto and off the decks using external equipment like Elevating Transfer Vehicles (ETVs) or Transfer Vehicles (TVs) equipped with friction drive systems.

Standard Storage Decks can support ULDs weighing up to 6,800 kg, in line with typical ULD system requirements. Lighter models for 5 ft ULDs have a lower capacity of 1,600 kg.

Yes, Lödige Storage Decks are designed for IATA-compliant handling of ULDs and support secure and accurate positioning within racking systems.

Absolutely. Storage Decks are frequently used for storing and buffering empty ULDs, especially in multi-level rack systems where fast retrieval is needed.

Thanks to their simple and durable design, Storage Decks require very little maintenance. Rollers are sealed and lubricated for life, reducing downtime and service costs.

Yes. Storage Decks are available in NEP (narrow edge presenting) and WEP (wide edge presenting) versions, and in sizes for 5 ft, 10 ft, 15 ft, and 20 ft ULDs to match different terminal layouts and ULD types.

ULDs are typically transferred using ETVs or other conveyor vehicles with friction drive systems. The deck design ensures smooth transfer and secure positioning.

Yes. While the decks themselves are passive, their position and use are fully integrated into automated storage systems, ensuring efficient ULD tracking and inventory control.

Yes, their modular design allows for easy integration into existing racking systems or as part of modernisation projects.