Automated Guided Vehicles (AGV) for Air Cargo Terminals

Flexible, autonomous transport solutions to streamline your ULD handling

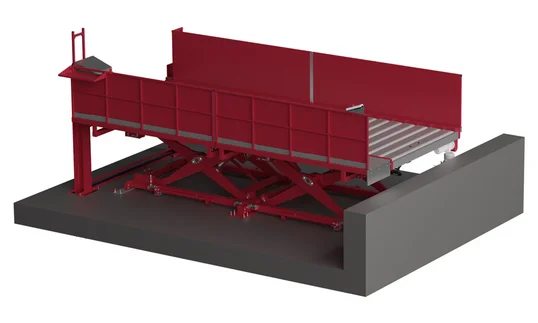

Efficient intra-terminal transport of Unit Load Devices (ULDs) is critical for modern air cargo terminals. Traditional solutions can struggle with flexibility, scalability, and peak-load management. Our Automated Guided Vehicles (AGVs) offer a dynamic and reliable alternative, seamlessly automating the transfer of ULDs between import/export areas, build & break zones, and storage locations.

AGV – The Smart Core of Automated ULD Handling

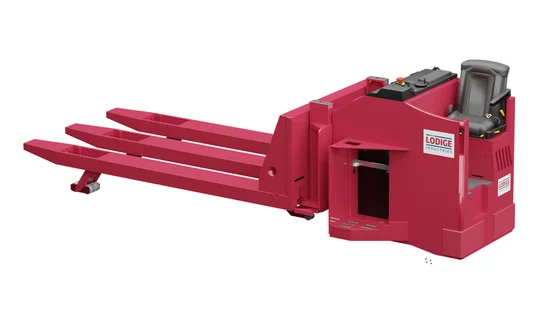

Lödige AGVs are intelligent, self-navigating vehicles for autonomous transport of 10 ft ULDs in NEP or WEP orientation at the standard conveying height of 508 mm. With natural navigation, laser scanners and lithium-ion batteries, they ensure safe, precise and continuous handling while reducing manual effort and bottlenecks.

Benefits of Lödige’s AGV for air cargo handling

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

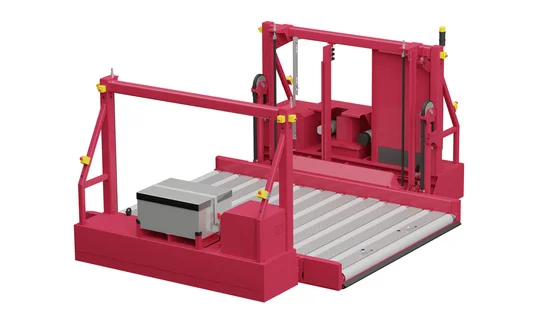

The AGV comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- Interface to any standard air cargo equipment incl. dollies, cargo pallet movers or manual handling areas

- Flexible connection between different stationary conveyor systems within the terminal

- Reduces space requirements due to compact design and unique arrangement of the drive units

- High operational safety for both operators and freight

- Permanent availability through efficient energy management and multiple vehicles

- Fully integrated into the warehouse management system (Lödige Cargo Professional)

- Loading and conveying at air cargo standard height of 508 mm

Technical Data

Description | 5 ft | 10 ft |

|---|---|---|

| Dimensions (L × W × H) | 3,075 × 1,730 × 570 mm | NEP: 3,790 × 2,790 × 570 mm WEP: 3,380 × 2,900 × 558 mm |

| Deck orientation | Wide Edge (WEP) | Narrow Edge (NEP) & Wide Edge (WEP) |

| Transfer height | 508 mm | 508 mm |

| Load capacity | 1,588 kg | 6,800 kg |

| Deadweight | 1,400 kg | 3,300 kg |

| Drive technology | Omnidirectional | |

| Max. travel speed | 1.5 m/s (up to 3.0 m/s) | |

| Max. acceleration | 0.3 m/s² | |

| Onboard conveyor | Roller conveyor (Conveying speed: 0.3 m/s) | |

| Battery type | Li-Ion | |

| Battery capacity | up to 220 Ah | |

| Charging | Inductive charging (Opportunity charging possibility) | |

| Charging time (20%-80%) | 1.5 h | |

| Navigation system | Natural navigation | |

| Stop precision | ± 10 mm | |

| Network connection | WiFi | |

| Safety features |

|

|

Automation Degree

Lödige Automated Guided Vehicles (AGVs) represent a fully automated solution specifically designed to autonomously manage intra-terminal transport tasks.

Operating without the need for additional infrastructure, these vehicles integrate seamlessly into terminal operations, automating the transfer of 10 ft ULDs between build & break zones, import/export areas, storage decks, and docks.

Controlled centrally by the Cargo Professional Suite, AGVs deliver consistent, safe, and efficient handling, significantly reducing manual intervention and ensuring optimal resource use and throughput, even at peak terminal loads.

Tools & Downloads

-

Flughafenlogistik

Broschüre (Englisch) -

Fahrerloses Transportsystem (FTS)

Technische Information (Englisch)

AGV successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

Lödige Industries has implemented AGVs at Swissport to streamline ULD transport within the terminal. The driverless vehicles connect key process areas with precision, enhancing safety, flexibility, and throughput. This reference project demonstrates how scalable automation can optimise internal cargo flows for leading ground handlers.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Ready to optimise your internal cargo flows?

Talk to us about Automated Guided Vehicles for your terminal.

FAQs

AGV stands for Automated Guided Vehicle. In Lödige systems, it moves ULDs autonomously between terminal zones like import/export areas, workstations, and automated storage systems.

Lödige AGVs can transport ULDs up to 15 ft and 6,800 kg in either NEP or WEP orientation, with precise alignment and seamless transfers.

No. The AGV uses natural navigation and laser-based obstacle detection. No floor tracks or beacons are required.

The routes are dynamically assigned via warehouse management systems (WMS) or logistics software. In combination with fleet management, the AGV can be easily integrated into digital logistics platforms.

Yes. With lithium-ion batteries and inductive charging, AGVs can operate 24/7 with minimal intervention.

It complies with DIN EN ISO 3691-4:2020-11 and EN13849, and includes: 2 laser scanners, LED lights, emergency stops, plate stops, and 360° PTZ cameras.

It achieves a stop precision of ±10 mm.

Both fully automated hubs and manual terminals benefit. AGVs reduce fixed infrastructure and human error while improving cargo flow reliability.

Yes. AGVs are designed to interface with Lödige slave pallets, FlexLoaders, racking systems, and powered conveyors.

- Dimensions (10 ft): up to 3,790 x 2,900 x 570 mm

- Load capacity: up to 6,800 kg

- Max speed: 3 m/s (driving), 0.3 m/s (conveying)

- Battery: Li-Ion, up to 220 Ah

- Navigation: Natural guidance with Wi-Fi connectivity