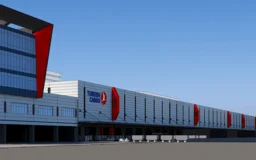

Made in Germany for the Mega-Airport Istanbul

Lödige Industries equips cargo terminal of Turkish Cargo

Lödige Industries will supply a new fully automated terminal with state-of-the-art technology for Turkish Cargo. When completed, the terminal will have a handling capacity of four million tons per year and a total area of 300,000 square meters. Lödige Industries is aiming to enable the expanding cargo airline to shift its freight activities to the new mega-hub.

Turkish Cargo is investing in their fleet to become one of top five provider in the air cargo industry. Due to the fast-growing airline, the existing cargo facility ran out of capacities and operations will be moved from Ataturk airport to new Istanbul Airport. Cargo activities will be handled at Ataturk airport until the new cargo terminal at Istanbul airport is ready for operation. The cargo capacity will increase from 1.2 million tonnes handled per year on 165,000m² up to 4 million tonnes per year on doubled footprint.

Istanbul Airport won "Best Airport in Europe" by International Airports Council (ACI) in 2021 and the "Airport of the Year" Award in 2021 and 2022. The airport also received the award for "Future projects-Infrastructure" at the World Architectural Festival in Berlin in 2016.

The new terminal provides higher quality and more efficient processes with diversified special cargo areas. This allows differentiated services for product groups as temperature-controlled storage (6,000m²), express cargo area (2,000m²) and 500m² for living animals. In addition, 5,000m² are provided for e-commerce and mail cargo as well as another 1,000m² for a high-security area handling valuable cargo. Freight handling for perishable goods, excess luggage, express luggage, domestic freight and general cargo will take place on two levels.

The equipment of the new cargo terminal will include automated high-bay warehouses with 17,000 storage bins, 30 stacking cranes, 15 lifters and an integrated warehouse management system (Lödige Cargo Professional) with a direct interface to the customer and freight management systems. The cargo terminal will be maintained on site by a local Lödige Industries service team and will also be connected to the Lödige Customer Care Centre in Germany, which will be able to quickly remedy system errors 24/7.

About Turkish Cargo

Turkish Cargo is one of the largest cargo airlines in the world, with a global network on all continents. The airline provides air freight services to more than 300 international destinations, with 86 direct cargo flights. With 30 percent growth in the second half of 2018, Turkish Airlines is also one of the fastest growing cargo airlines in the world. For this, the airline received the "Cargo Airline of the Year" Award from Air Cargo Week magazine in 2018.

Project details

Components

- 17,000 storage bins

- 1,340 ULD storage positions

- 30 stacking cranes

- 15 lifters

- integrated warehouse management system (Lödige Cargo Professional) with a direct interface to the customer and freight management systems

Challenges for Turkish Cargo as fast growing airline and the new Mega Hub

- With 30 percent growth in the second half of 2018, Turkish Airlines is one of the fastest growing cargo airlines in the world.

- Turkish Cargo constantly updates its service portfolio in handling not only general cargo but special cargo aswell such as perishable, valuable or pharma goods.

- Thus, the existing cargo facility at Ataturk Airport ran out of capacity.

- With the ambition to become one of the top five provider in the air cargo industry, the new cargo facility needs to provide reliable and performing state-of-the-art technology.

Solution and Benefits for the Turkish Cargo Mega Hub

- Due to the increasing capacities, Turkish Cargo decided to build up a new 300,000 m² cargo facility

- The Cargo Handling System will incorporate automated high-bay warehouses with 17,000 storage bins, 30 stacking cranes, 15 lifters

- State-of-the-art technology such as an integrated warehouse management system will enable Turkish Cargo to optimise its performance

- The cargo capacity will increase from 1.2 million tonnes handled per year on 165,000m² up to 4 million tonnes per year on doubled footprint.

Please contact us

We look forward to your message.