Efficient goods receipt and dispatch with maximum inventory control

Market leading goods in and out solutions from Lödige Industries

The goods receipt and dispatch processes are central to any manufacturing, warehouse or distribution centre. Without a strong goods in process, all downstream activities are in peril. Without an efficient dispatch set-up, time to market and therefore profit will suffer. Lödige Industries receipt and dispatch workflows solutions, whether on a stand-alone basis or as part of a comprehensive warehouse system, will improve warehouse efficiency and the flow of stock.

Our WMS supports a range of manual to fully automated receiving, conveying and dispatch methods. This helps ensure maximum continuous inventory accuracy and smart storage routing for efficient storage and retrieval.

Trucks arriving at the gate are directed to numbered parking lots or to our receiving truck docks, designed to speed up loading and unloading processes. Our solutions range from simple flexible scissor lifting tables with a lifting capacity of 1,000 kg to complex truck lifts with a maximum height of 12.5 m and lifting up to 100 tons.

"The majority of inventory errors occur at receiving and putaway. Without a rigorous goods in process, it’s difficult to establish and maintain inventory accuracy."

(Guy Walker, Managing Director Middle East, Lödige Industries)

Goods receipt processes that still rely on the “circle, sign and date” method are not only prone to errors but may find out too late that they have less than the expected inventory in stock. Manual goods in processes are not only error prone and intransparent but also labour intensive, inefficient and slow. For e-commerce and fulfilment centres this is costly. The longer it takes for items to register as available, the larger the missed sales opportunities. Goods receiving may seem a small step in the supply chain, but if done well, sets the stage for success throughout the distribution center.

Our goods receipt and dispatch solutions:

Guarantee the success of your warehouse operations

Market leading goods receipt and dispatch solutions from Lödige Industries

Lödige Industries goods receipt and dispatch solutions at a glance:

Truck Loading & Unloading Solutions

Moving goods into and out of your warehouse in an efficient manner is a major challenge - high costs, queueing and inefficiency can all arise when processes are suboptimal. Goods in and out solutions from Lödige Industries can make your receipt and dispatch operations more efficient, accident and error free, with a positive knock-on effect on the rest of your operations.

Replenishment Solutions

Efficient and fast unloading and transportation are crucial in optimising internal workflows and increasing throughput. Automated conveying and storage solutions decrease accidents, line delays and damage, by reducing the need for human intervention and forklift traffic around operators our conveyor systems and make warehouse operations safer. Automating pallet or case replenishment as well as inventory replenishment significant efficiency gains can be made.

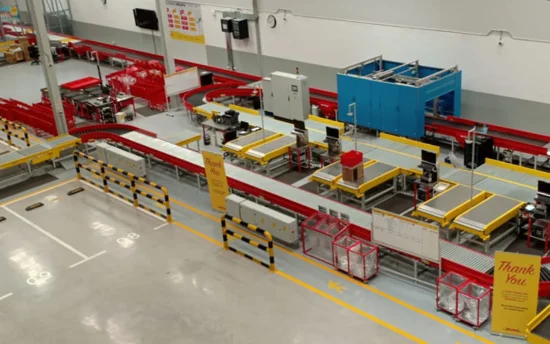

Sortation

When efficiency is a prime goal of warehousing operators, incoming and dispatch ready goods need to be verified, sorted and stored quickly and accurately. Automated sorting solutions from Lödige Industries move and sort large volumes of goods rapidly and error-free, allowing operators to export or import higher volumes in a smaller space with less manpower and increased productivity.

Warehouse Management Systems

Plan, control and track your material flow in real time - Efficiency in receiving, storing and shipping goods is more important than ever. Databased software controls from Lödige Industries give warehouse managers ultimate inventory and process visibility, informs them of what is occurring inside the facility and throughout the supply chain in real time and enables them to automate material handling, collect, attribute and analyse data and create new areas of business opportunity.

Want to upgrade your existing facility?

Or do you need support with the maintenance of your system or a system health check?

Storage & Conveying Solutions by Lödige Industries

Enabling our customers to achieve their goals

Looking for more?

Looking for production logistics solutions?

Lödige Industries provides integrated solutions for production processes in many industries.

Please contact us

We look forward to your message.