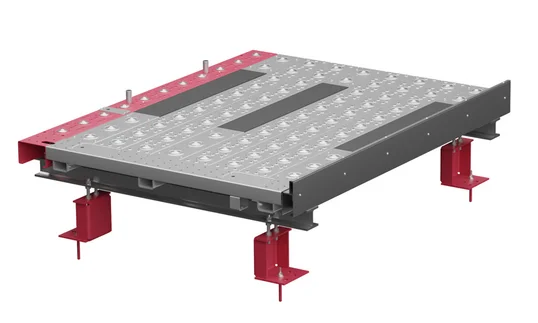

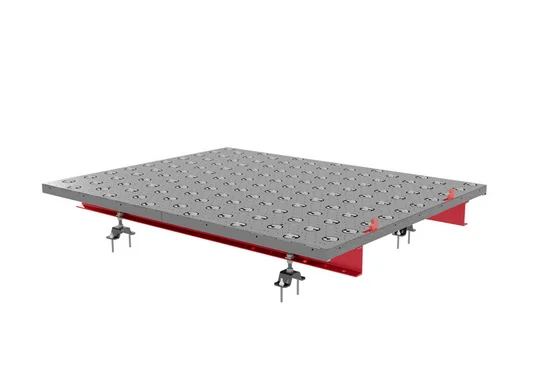

Castor Deck – Modular ULD Handling for Flexible Cargo Operations

Efficient manual cargo handling for flexible terminal processes

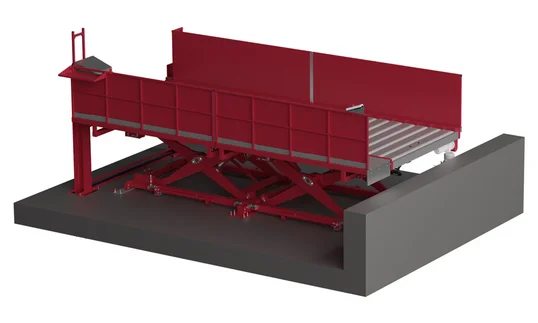

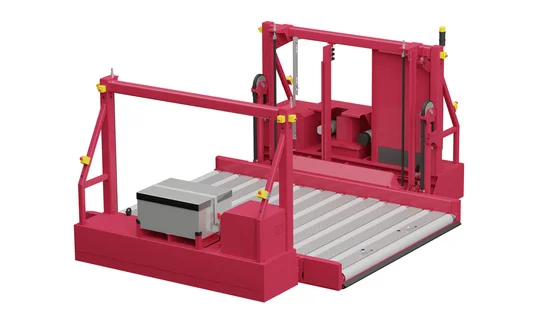

Castor Decks enable the manual, safe, and flexible movement of ULDs within air cargo terminals. They provide a simple solution for multidirectional ULD transfers, used wherever maximum flexibility is required – in Build & Break processes, Intra Terminal Transport, or at Airside Interfaces.

Flexible ULD Handling Made Easy

Lödige Castor Decks are modular, heavy-duty platforms designed for multi-directional manual ULD movement and storage. With customisable sizes, ergonomic working heights (203 mm or 508 mm), and optional features like power drive units or weighing systems, Castor Decks optimise manual cargo handling. Ideal for buffer zones, Build & Break areas, truck docks, or cool rooms.

Benefits of Lödige’s Castor Deck

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Castor Deck comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- Painted finish or hot-dipped galvanised steel for external, cold or perishables environment

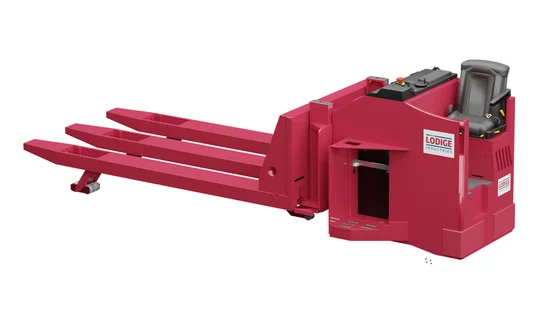

- PDU (Power Drive Unit) for power assisted transfer of ULDs

- Scaleable

- Manual and pneumatic stops

- With fork tine pockets

- Scale

- Litter skirts

- Shipping inside closed container possible

Technical Data

Description | 10ft section |

| Capacity | 6,800 kg |

| Length | 3,315 mm |

| Width | 2,600 mm |

| Transfer height | 203 mm & 508 mm |

| Capacity per castor | 250 kg |

Automation Degree

Castor Decks are a manual handling solution by design, offering high flexibility and low complexity. The automation level can be increased with Power Drive Units or by integrating into automated cargo handling systems using AGVs, Transfer Vehicles, or Roller Conveyor networks.

This modular approach makes Castor Decks a reliable choice for cargo terminals that require scalable solutions—from simple manual operations to automated air cargo workflows.

Tools & Downloads

-

Air Cargo Terminal Equipment

Brochure, (07-2025)

Castor Decks successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

Lödige Castor Decks enabled smooth multi-directional ULD handling, supporting one of Asia’s busiest express hubs with proven reliability and flexible integration.

Explore how Turkish Cargo enhanced their cargo handling efficiency and throughput at the state-of-the-art Istanbul facility with advanced solutions from Lödige Industries.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Let’s optimise your cargo terminal.

Speak with our experts to define your optimal equipment + software setup.

FAQs

Castor Decks enable manual, multi-directional movement of ULDs. They are commonly used in build & break zones, buffer areas, cold storage, and truck docks.

Yes. The castor grid, spacing, and structural design follow IATA ULD handling standards. Each deck is engineered to prevent container damage and ensure safe movement.

Castor Decks are typically designed for basically all ULDs.

Yes. Versions with hot-dip galvanised surfaces and stainless steel castors are available for use in cold rooms or on the apron.

Standard Castor Decks support up to 6,800 kg per 10 ft section. Individual castors are rated for 250 kg each.

Yes. Most Castor Decks offer ±50 mm height adjustment for ergonomic alignment with surrounding systems and equipment.

Optional features include manual stops, side guides, mobile stops, and litter skirts. These improve ULD positioning and prevent accidental movement.

While Castor Decks are primarily used for manual handling, they are often installed alongside powered systems like roller decks, turntables or FlexLoaders to bridge between manual and automated processes.

The modular design allows for easy customisation, reconfiguration, and integration into complex terminal layouts — even in areas with limited space.