手动 ULD 存储解决方案

为航空货运站提供灵活高效的手动存储设备

高效的货物处理始于安全可靠的仓储。手动 ULD 存储为在码头内组织和缓冲 ULD 提供了一种灵活、经济高效的方式。它是一个模块化的起点,以后可通过自动化进行扩展。典型的使用案例包括低吞吐量操作、高峰期额外的缓冲空间,或连续使用 ULD 的货代和快递公司。

手动 ULD 存储如何工作

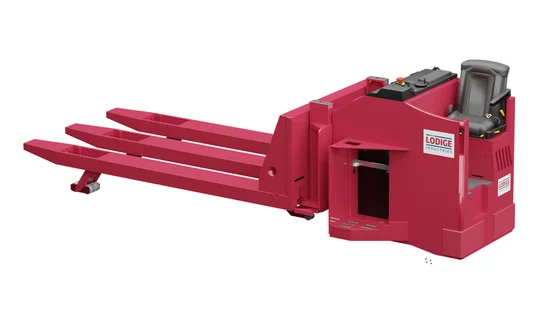

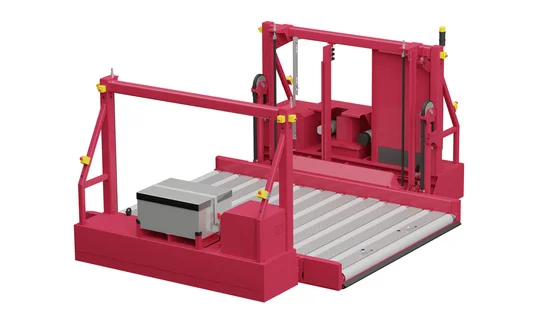

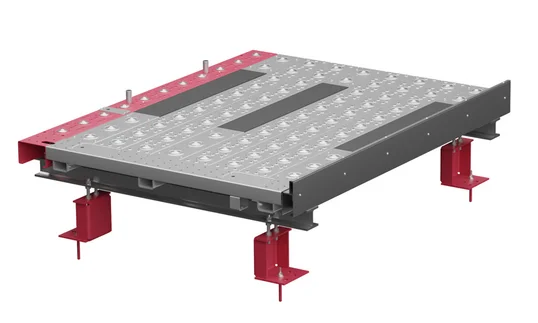

手动 ULD 存储为集装箱和托盘提供指定区域,确保安全放置和快速存取。我们的模块化系统,如ULD 支撑托盘、脚轮甲板、球形甲板和滚轮甲板,便于人工搬运、定位和存储 5 英尺、10 英尺和 15 英尺单元,完全符合 IATA 标准。货物托盘移动装置或用于两层存储的FlexLoader支持 ULD 支撑托盘上的移动。

罗地格手动 ULD 仓储解决方案的优势

我们的解决方案专为可靠的货物存储而设计,通过最大限度地利用空间、确保安全装卸和支持与码头运营的灵活整合,带来可衡量的效益。

相关产品

探索用于 ULD 装卸的设备

了解相关产品,以支持您的码头处理 ULD 的每个步骤。从接收、存储到转运,这些解决方案可确保高效、安全并顺利融入您的货物流程。

从陆侧到空侧 - 探索流程

浏览航空货物装卸的关键步骤,了解我们的解决方案如何支持每个流程。

规划您在 ULD 存储方面的下一步行动。

请与我们的专家讨论,找到合适的解决方案--从手动设置到全自动系统。

常见问题(FAQ)

装在支撑托盘上的 ULD 由货物托盘搬运车搬运,如果需要进入两层仓库,则由FlexLoader搬运。在脚轮甲板和球形甲板上,ULD 由工作人员手动操作,并分配到指定位置。

是的,它可以逐步扩展,例如整合摩擦动力甲板、转运车或全自动货架。

绝对。灵活的人工设置通常在人流量大的时候用作缓冲空间,确保货物流动不中断。

是的。手动系统可无缝连接并扩展到半自动或全自动解决方案。即使在灵活的存储区域,也可以使用手持式扫描仪可靠地跟踪 ULD 位置,确保透明度并与码头管理系统集成。

是的,所有部件都确保按照国际航空运输协会的标准进行处理和储存。

是的,这些解决方案适用于温控区以及危险品或 OOG 货物区。

存储位置在码头管理系统中进行标记和登记,确保透明度和可追溯性。

它广泛应用于对吞吐量要求不高的码头,以及连续处理 ULD 的货代或快递公司。