Optimal Handling for Air Cargo Build & Break

Ball Decks enable safe, ergonomic, and efficient handling of ULDs of all sizes. Designed for manual, multi-directional cargo movement, they simplify build & break operations, support flexible workstation layouts, and integrate seamlessly with other terminal equipment.

Efficient and Ergonomic Cargo Handling

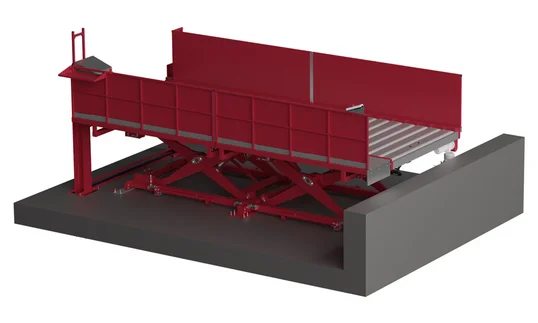

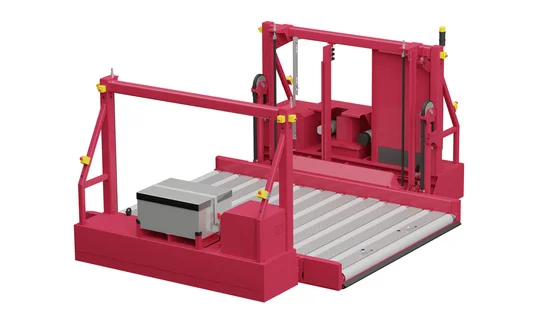

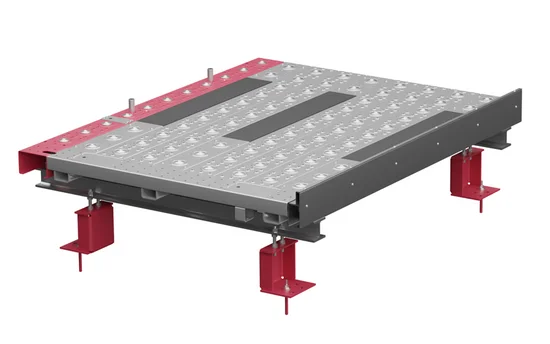

Lödige Ball Decks are modular, non-powered decks for the manual handling of ULDs. Equipped with robust ball transfer units, these decks allow smooth multi-directional movement, making ULD positioning fast, effortless, and safe. With pneumatic brake pads and pin stops, the decks ensure stable ULD positioning at an optimal ergonomic height.

Benefits of Lödige’s Ball Deck

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Ball Deck comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- Available for 5 ft, 10 ft, 15 ft and 20 ft ULDs, it offers multi-directional movement with modular layouts.

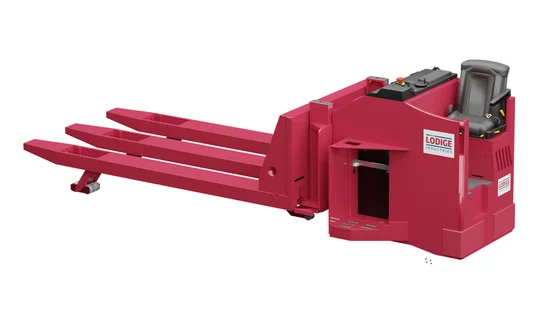

- Workstation for Build & Break for 5 ft ULDs with pneumatic braking pads

- Options include stops, side guides, weighing facilities, litter skirts and power drive units, ensuring flexible integration into any terminal design.

Technical Data

Description | 5ft workstation with brake pads | 10 ft section |

| Capacity | 1,600 kg | 6,800 kg |

| Length | 2,600 mm | 2,600 mm |

| Width | 1,675 mm | 3,204 mm |

| Transfer height | 508 mm | 508 mm |

| Ball diameter | 30 mm | 30 mm |

| Type of brake pad and pin stop activation | Pneumatic | - |

Automation Degree

Ball Decks are a manual handling solution by design, offering high flexibility and low complexity. The automation level can be increased with pneumatic brake pads or by integrating into automated cargo handling systems using AGVs, Transfer Vehicles, or Roller Conveyor networks.

This modular approach makes Ball Decks a reliable choice for cargo terminals that require scalable solutions—from simple manual operations to automated air cargo workflows.

Tools & Downloads

-

Luftfrachtanlagen - Terminal Equipment

Broschüre (Englisch)

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Let’s optimise your sorting & buffer zones

Speak with our experts to define your optimal equipment

Frequently Asked Questions (FAQs)

Ball Decks can support loads up to 6,800 kg per 10ft section, ensuring secure handling for even the heaviest ULDs.

The standard transfer height for Ball Decks is 508 mm, providing optimal ergonomic conditions for loading and unloading.

Yes, Ball Decks can be installed outdoors. They feature corrosion-resistant, weatherproof finishes suitable for harsh conditions.

Yes, Ball Decks feature pneumatic brake pads and manual pin stops, preventing unintended cargo movements and enhancing operational safety.

Yes, Lödige Ball Decks fully comply with international IATA standards, ensuring global operational safety and quality.

The modular design enables easy scalability and flexibility to match changing operational demands quickly.

Minimal maintenance is required, with easily accessible modular components simplifying servicing and reducing downtime.

Yes, friction-powered drive units can be optionally integrated to assist manual cargo movement and reduce operator fatigue.

Ball Decks are designed for seamless integration with other Lödige cargo handling systems, enhancing operational flexibility.

Installation is straightforward due to modular components designed for quick assembly, minimizing downtime.

Yes, Ball Decks are adaptable and can effectively manage different ULD sizes, accommodating diverse cargo requirements.

Ball Decks can be specially configured for cold storage, using materials and components that maintain optimal performance in low temperatures.