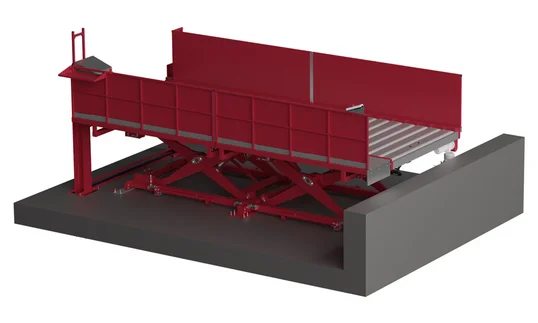

FlexLoader – Multifunctional ULD Transfer System

Versatile, Mobile, IATA-compliant

Looking for mobile ULD transfer without fixed infrastructure? The Lödige FlexLoader provides unmatched flexibility for air cargo terminals, forwarding agents, and logistics providers handling air freight ULDs. Combining truck dock, pallet transporter, and vertical lift functions, it efficiently manages ULDs across varying heights and diverse areas, ensuring safe and fully IATA-compliant handling.

One Vehicle, Many Possibilities

The Lödige FlexLoader is a battery-powered, electro-hydraulic vehicle designed for flexible transport and precise lifting of ULDs. Its multifunctional design enables seamless transfer of cargo units between lorries, dollies, workstations, storage racks, and conveyor systems. Integrated powered roller decks and wireless remote control enhance operational safety and ease of use.

With a load capacity of 6,800 kg and lifting ranges up to 3,050 mm (FlexLoader XL), it transfers ULDs via powered rollers at speeds of up to 1 m/s. Full control is provided by wireless remote operation and omnidirectional drive.

See the Lödige FlexLoader in action

This multifunctional unit combines the roles of a truck dock and a pallet mover in one mobile system. Ideal for environments where infrastructure needs to remain flexible – from air cargo terminals to forwarding agents and shipping departments.

Benefits of Lödige’s FlexLoader

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

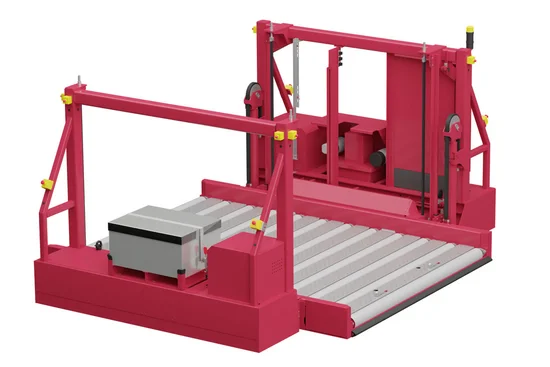

FlexLoader XL - Reaching the second level

The FlexLoader XL offers an optional lifting height of up to 3.05 meters and can include an operator cabin for enhanced safety and comfort. Equipped with side wire mesh, a plexiglass window, and a secured hinged door with safety monitoring, the cabin allows controlled operations, with some functions limited to creep speed for safety.

Proven Features & Options

FlexLoader

The FlexLoader comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features & Options

- Handling and horizontal transfer of 5 ft, 10 ft & 15ft ULDs

- Alignment and transfer of ULDs at various heights of lorries, dollies and stationary equipment and racking systems

- On demand connection of lorries and workstations or storage systems

- Maximum transfer heights of 1,600 mm (L) and 3,050 mm (XL)

- XL version can transfer to first storage level

- Friction wheels to drive non powered storage decks

- Option: Cabin for XL version

Technical Data

Description | FlexLoader L | FlexLoader XL |

|---|---|---|

| Capacity | 6,800 kg | |

| Length | 3,500 mm | |

| Width | 4,430 mm | |

| Height | 2,200 mm | 3,480 mm |

| Elevation in lowest position | 203 mm | |

| Elevation in top position | 1,600 mm | 3,050 mm |

| Lifting Stroke | 1,400 mm | 2,850 mm |

| Deadweight incl. Battery | 4,300 kg | 5,000 kg |

| Max. ULD category | 15 ft | |

| Deck orientation | Narrow Edge (NEP) | |

| Lifting speed | 0,05 m/s | |

| Driving speed | up to 1 m/s | |

| Conveying speed | 0,3 m/s | |

| Battery type | Lead-acid | |

| Battery capacity | 300 Ah | |

Automation Degree

Adaptable to any operational setup, the Lödige FlexLoader supports different levels of automation within the terminal. In manual operation, it is remote-controlled by an operator for flexible ULD handling across various terminal areas. In semi-automated environments, predefined movement parameters assist docking and transfer, improving precision and speed.

In fully automated systems, the FlexLoader connects to the Cargo Professional Suite for process coordination and status monitoring, ensuring consistent data flow within the terminal. It is typically used in buffer zones or manual interface areas, providing flexible support and ensuring smooth interaction between automated and manual workflows.

Tools & Downloads

-

Luftfrachtanlagen - Terminal Equipment

Broschüre (Englisch)

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

Ready to enhance your ULD handling efficiency?

Talk to our experts about integrating the Lödige FlexLoader into your terminal setup – for flexible, safe and efficient ULD transfers.

FAQs

It combines vertical lifting and ULD transport to link trucks, conveyors, and pallet areas — ideal for efficient terminal flow without fixed infrastructure.

It manages ULDs up to 15 ft long and 6,800 kg in weight, with base plates up to 3,175 x 2,440 mm.

FlexLoader L lifts up to 1,600 mm. FlexLoader XL reaches 3,050 mm and supports an optional operator cabin for high-altitude control.

Yes. A 48 V / 300 Ah battery system supports multiple hours of operation with fast charging capability (400 V input).

All motion and lifting functions are controlled by wireless remote, enabling safe operation from optimal viewing angles.

Yes. The XL model enables vertical transfers to/from mezzanine decks or multi-tiered ULD storage racks.

It drives at up to 1 m/s, lifts at 0.05 m/s, and conveys ULDs at up to 0.3 m/s using powered rollers.

The FlexLoader includes finger stops, photocell sensors, and optional cabin protection to ensure IATA ULD Care-compliant operation.

FlexLoader L: 3,500 x 4,425 x 2,200 mm

FlexLoader XL: 3,500 x 4,430 x 3,480 mm

Weight (incl. battery): ~4,300 – 5,000 kg.