ETV Storage Systems for ULDs

Automated high-bay storage for maximum capacity and transparency

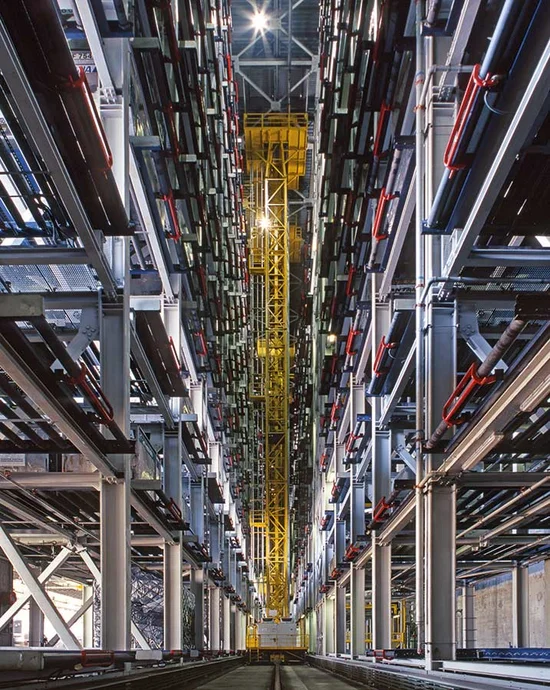

Air cargo terminals handling large volumes need space-efficient and reliable ULD storage solutions. ETV (Elevating Transfer Vehicle) high-bay systems provide fully automated multi-level storage with vertical and horizontal transfer combined in one vehicle. This ensures maximum use of vertical and horizontal space, transparent inventory management and secure, IATA-compliant handling.

Maximising Vertical and Horizontal Space

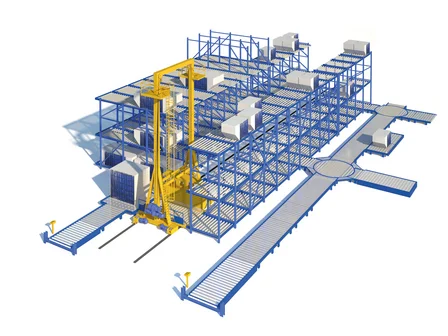

ETV systems move ULDs vertically and horizontally within high-bay racks, storing and retrieving units on demand. Each vehicle runs along dedicated aisles, lifting and placing ULDs into storage decks across multiple levels. This integrated movement enables safe and reliable operation while making the most of building height and available space. ETV high-bay systems are ideal for large-scale cargo hubs where capacity, transparency and automation are critical.

Benefits of Lödige’s ETV Storage Systems

Focused on space utilisation and handling efficiency, our storage solutions deliver measurable benefits by optimising capacity, ensuring safe ULD handling and enabling seamless integration with terminal workflows.

What is the difference between ETV and Lift & Run storages?

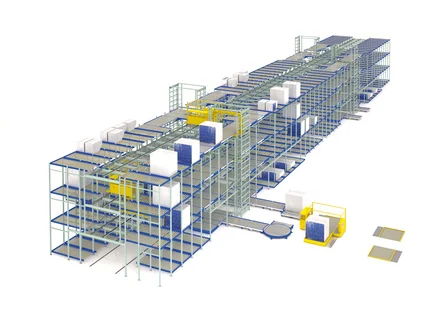

Both ETV and Lift & Run storage systems offer fully automated, high-performance ULD storage designed for large-scale cargo terminals. ETV storage systems combine vertical and horizontal movements in one vehicle, making them a proven choice for long high-bay aisles and maximum use of vertical space. Lift & Run systems, by contrast, separate lifting and transfer into dedicated units that work in parallel, giving faster access to storage positions and high flexibility under peak loads.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Plan your next step in ULD storage.

Talk to our experts to find the right solution – from manual setups to fully automated systems.

Frequently Asked Questions (FAQs)

The capacity depends on rack height, aisle length and system layout. A single ETV aisle can store hundreds of ULDs.

Yes, the system can be configured to support all standard ULD sizes in single- or double-deep configuration.

Typical transfer and retrieval times are under 60 seconds per ULD, depending on layout and interfaces.

Fallback routines and manual intervention modes are available. Multiple aisles can be installed for redundancy.

Yes, insulated cool rooms with integrated storage decks and sectional doors can be included in the system.