Manual ULD Storage Solutions

Flexible and Efficient Manual Storage for Air Cargo Terminals

Efficient cargo handling starts with secure and reliable storage. Manual ULD storage provides a flexible and cost-effective way to organise and buffer ULDs inside the terminal. It serves as a modular starting point that can later be expanded with automation. Typical use cases include low-throughput operations, additional buffer space during peak times, or for forwarders and courier companies that work with ULDs on a continuous basis.

How Manual ULD Storage Works

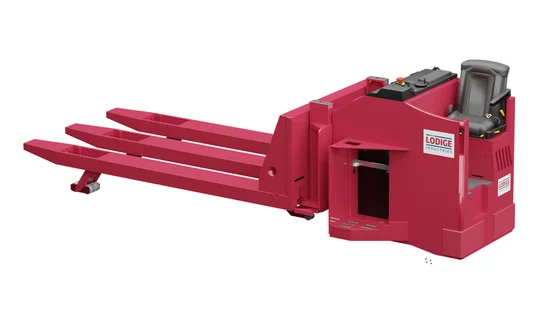

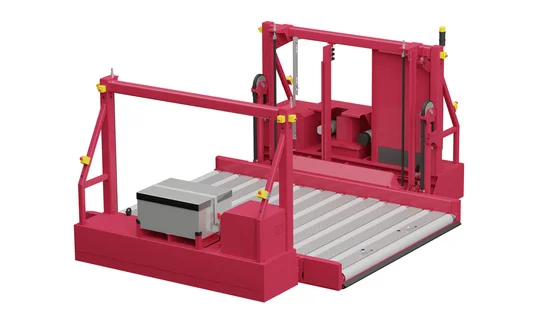

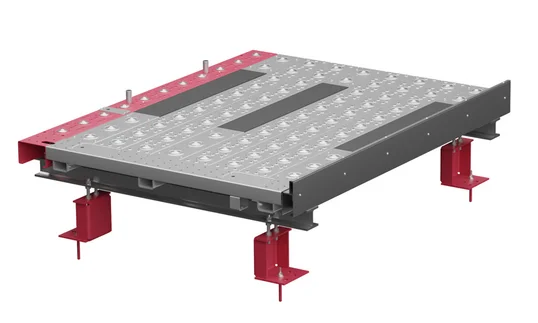

Manual ULD storage provides designated areas for containers and pallets, ensuring safe placement and quick access. Our modular systems such as ULD Support Pallets, Castor Decks, Ball Decks and Roller Decks facilitate manual handling, positioning, and storage of 5 ft, 10 ft and 15 ft units in full IATA compliance. Movement on ULD Support Pallets is supported by a Cargo Pallet Mover or a FlexLoader for two-level storage.

Benefits of Lödige’s Manual ULD storage solutions

Designed for reliable cargo storage, our solutions deliver measurable benefits by maximising space utilisation, ensuring secure handling and supporting flexible integration into terminal operations.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Plan your next step in ULD storage.

Talk to our experts to find the right solution – from manual setups to fully automated systems.

Frequently Asked Questions (FAQ)

ULDs on support pallets are handled with a Cargo Pallet Mover, or with a FlexLoader if access to two-level storage is required. On Castor Decks and Ball Decks, ULDs are manually manoeuvred by personnel and assigned to their designated positions.

Yes, it can be expanded step by step, for example by integrating friction-powered decks, transfer vehicles or fully automated racks.

Definitely. Flexible manual setups are often used as buffer space during high-traffic times, ensuring cargo flows remain uninterrupted.

Yes. Manual systems are designed to seamlessly connect and scale up to semi- or fully automated solutions. Even in flexible storage areas, ULD positions can be tracked reliably using handheld scanners, ensuring transparency and integration with the terminal management system.

Yes, all components ensure handling and storage according to IATA standards.

Yes, these solutions are suitable for temperature-controlled zones as well as areas for dangerous goods or OOG cargo.

Storage positions are marked and registered in the Terminal Management System, ensuring transparency and traceability.

It is widely used by terminals with low-throughput requirements and by forwarders or courier companies that work continuously with ULDs.