Cargo Pallet Mover – Flexible ULD Transport for Terminal Operations

former: Slave Pallet Mover

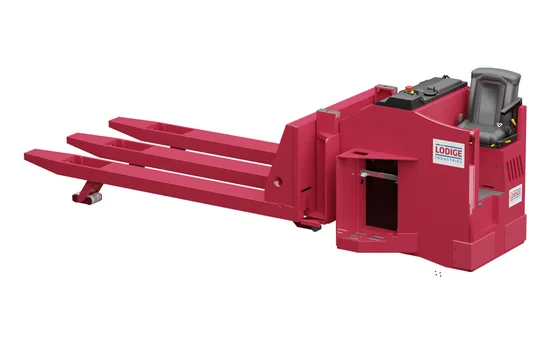

Need to move ULDs safely and efficiently — without relying on fixed infrastructure? The Cargo Pallet Mover is purpose-built for transporting ULD Support Pallets within your terminal. Whether you're dealing with peak traffic or spatial constraints, this battery-powered vehicle adds agility to your cargo operations — safely, precisely, and IATA-compliant.

Move ULDs with Power and Precision

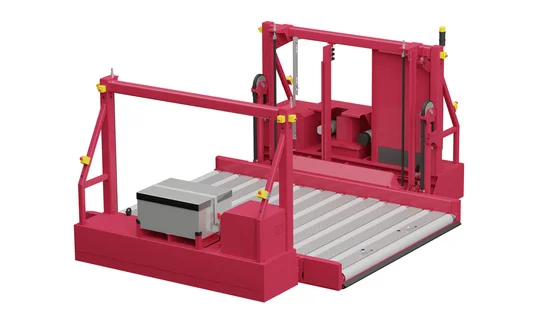

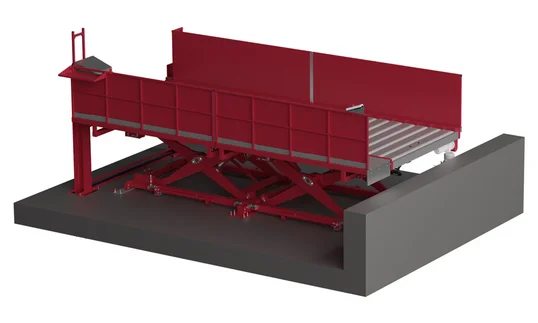

The Lödige Cargo Pallet Mover is a maneuverable, battery-powered transport vehicle for ULD Support Pallets carrying ULDs up to 15 ft and 7,500 kg. Three wide forks allow precise pick-up at system heights of 203 mm and 508 mm. With electric power steering and a robust lift mechanism, it ensures safe transfer between landside interface, build & break zones, storage positions, and the airside interface.

Benefits of Lödige’s Cargo Pallet Mover

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Cargo Pallet Mover comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features & Options

Features

- Ergonomical operator station with comfortable, air suspended driver seat

- Steering wheel intregrated into armrest

- All-around view

- Small turning radius

- Dead man control

- Horn

Safety Options

- Protective roof (grille)

- Seat belt safety (drive only with seat belt fastened)

- Fire Extinguisher

Operating Options

- Reverse Alarm

- Diagnostic software

- Visible reserve warning light (blue)

- Lighting Package (Bar inlcuding Flashing beacon (amber colour), Head lights (facing driveway), Working lights (facing freight))

- Flashing beacon (amber colour) - installed on mast

- Mirror (only with Lighting package or Flashing beacon)

- Lead-acid and lithium-ion batteries are possible

- Battery changing cradle as an accessory

Technical Data

Description | |

| Capacity (incl. ULD Support Pallet) | 7,500 kg (ULD: 6,800 kg) |

| Max. ULD size | 15 ft (wings only laterally) |

| Deadweight without battery | 3,100 kg |

| Length | 3,850 mm |

| Width | 2,050 mm |

| Height | 1,600 mm |

| Turning radius | 3,540 mm |

| Number of tines | 3 |

| Fork length | 2,400 mm |

| Fork width | 320 mm |

| Fork height (upper side to floor) | 115 mm |

| Lift stroke | 345 mm |

| Max. transfer height | 508 mm |

| Driving speed | up to 2 m/s (7 km/h) |

| Wheel lining | Polyurethan |

| Battery type | Lead-acid or lithium-ion |

| Battery capacity | up to 560 Ah |

| Battery recharging time | 8 h (for 560 Ah) |

Automation Degree

Cargo Pallet Movers are semi-automated, battery-powered vehicles designed for efficient ULD transport within terminals. While operator-driven, they support assisted navigation and precise docking at storage and transfer points. They can integrate seamlessly into warehouse management systems (WMS) and the Lödige Cargo Professional Suite, ensuring smooth coordination with terminal control and automation systems. Ideal for build & break areas, truck docks, and flexible ULD handling tasks.

Tools & Downloads

-

Luftfrachtanlagen - Terminal Equipment

Broschüre (Englisch)

Cargo Pallet Mover successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

The new COOL Nordic cargo hub at Helsinki Airport, known in the industry as the "COOL Terminal" is the most modern air cargo terminal in Europe and one of the newest air freight hubs in the world.

Lödige’s flexible approach ensured SCSC achieved the functionality and capability needed to create a world class facility.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

FAQs

It can carry up to 7,500 kg, including the ULD and its support pallet.

The Cargo Pallet Mover is designed to move Lödige ULD Support Pallets at standard transfer heights of 203 mm and 508 mm.

Yes. With electric power steering and a compact turning radius, the unit operates easily in narrow terminal areas.

Up to 10 hours of continuous use under standard operating cycles. Fast charging and battery exchange systems are available.

Yes. The mover supports ULD handling in accordance with IATA AHM 911 standards.

Yes. Unlike forklifts, which are not suitable for lifting ULD Support Pallets, the Cargo Pallet Mover is specifically designed for this task.

Within the terminal, including build & break areas, staging zones, and the airside interface — not on the apron.