Intra Terminal Transport

Reliable Movement of ULDs & Cargo Inside the Terminal

Internal transport connects all major process areas within the cargo terminal – from truck docks and storage systems to build & break stations and airside handover. To ensure short turnaround times, cargo must move quickly, safely, and without disruption. Lödige offers flexible and scalable transport solutions including AGVs, transfer vehicles and conveyor systems – all tailored to your operational setup and integrated with smart software.

How Cargo Moves Inside the Terminal

During operation, all kinds of cargo are moved between acceptance, storage, processing and aircraft handover. Transport may be manual, vehicle-based or fully automated, using solutions such as AGVs, transfer vehicles, pallet movers or conveyor systems. Special cargo zones like cool storage, DGR and out-of-gauge areas are fully integrated.

For internal transport, we combine four core strengths: products, software, system planning and service. Together, they ensure safe, efficient and scalable ULD transfers – connecting all terminal areas from manual movers to fully automated AGV fleets.

Benefits of Lödige's Intra Terminal Transport Solutions

Focused on operational workflows, our process solutions create tangible benefits by streamlining handling steps, reducing turnaround times and enabling smooth coordination across all air cargo terminal areas.

Flexible Automation for Intra Terminal Transports

From manual acceptance to fully integrated handover

Intra-terminal transport systems can be implemented at varying levels of automation, depending on terminal layout, operational complexity, and throughput requirements. From forklift-based transfer to fully automated routing, each option supports seamless cargo flow between landside, storage, build & break and airside zones.

Fully automated

Fully automated transport systems provide seamless, high-capacity cargo flows with minimal manual intervention. They are designed for large terminals with high throughput demands and strict performance requirements. Functions include autonomous ULD routing and handover, system-wide transport coordination, real-time optimisation and tracking, and optimised cargo flow.

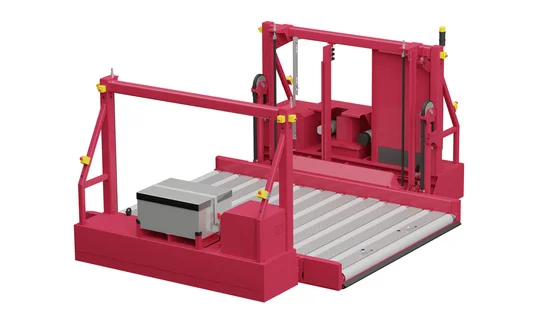

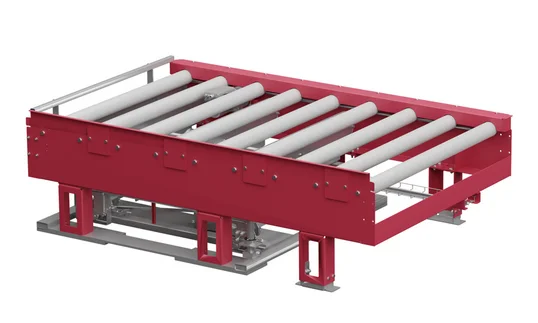

Typical Equipment | Software Components |

| • AGV ULD and Consignment (Inhouse Pallets) • Elevating Transfer Vehicle • Transfer Vehicle • Hoist • Roller Deck • Turntable • Turntable with Right-Angle Deck • Right-Angle Deck | Cargo Professional Suite (TMS) with Cargo Control and Cargo Direct Modules/ Functions: • ULD Control System • Pallet Control System • Live Operation Displays • Euipment Diagnostic System • AGV Fleetmanagement |

Semi-automated and mobile

Semi-automated transport systems reduce manual effort and improve process consistency, making them ideal for terminals aiming to boost performance without moving to full automation. Functions include mobile transport between zones, handover at defined transfer points, and route and status monitoring.

Typical Equipment | Software Components |

|---|---|

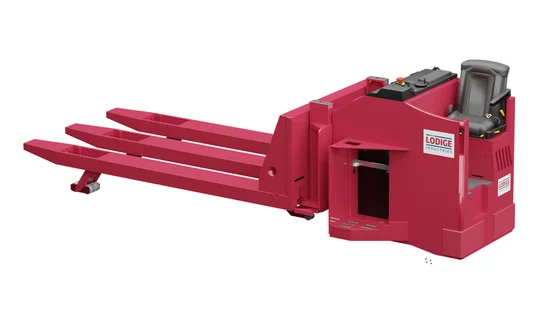

| • FlexLoader • Cargo Pallet Mover • ULD Support Pallet • Forklifts equipped with Forklift Guidance System • Skyfork for feeding workstations with consignments • Castor Deck with PDU | Cargo Professional Suite (TMS) with Cargo Control Modules/ Functions: • Forklift Guidance System |

Manual & Operator-Driven Systems

Manual transport provides operational flexibility and is commonly used in terminals with less standardised flows or during off-peak times. Forklifts move ULDs and in-house pallets between defined positions, with support from castor or roller decks where necessary.

Typical Equipment | Software Components |

| • Cargo Pallet Mover • ULD Support Pallet • FlexLoader • Castor Deck • Ball Deck • Forklift | - |

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

Discover Solutions for Consignment Handling

Explore related products that make consignment handling more efficient, compliant and scalable. Each solution contributes to secure storage, reliable processes and seamless integration into your terminal setup.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Planning or upgrading internal transport?

Our experts are ready to support.

Frequently Asked Questions (FAQs)

Intra terminal transport refers to the movement of cargo between different process areas inside the terminal – such as landside interface, storage, build & break, and airside.

Depending on automation level and layout, common systems include AGVs (automated guided vehicles), cargo pallet movers, roller conveyors, and chain conveyors.

Yes. Fully automated solutions use software-controlled vehicles or conveyors to manage cargo transfers 24/7 with high precision and traceability.

Each movement is registered in the Terminal Management System (TMS) – Cargo Professional Suite. Cargo is tracked in real time, including origin, destination and current position.

Yes. Transport equipment is compatible with IATA-standard transfer heights (203 mm and 508 mm), and can interface with docks, racks, and workstations. Our solutions are specifically designed for safe and efficient transport of dangerous goods, temperature-controlled cargo, and out-of-gauge cargo.

Absolutely. Transport systems are designed to handle OOG cargo, dangerous goods, and temperature-sensitive shipments safely and efficiently.

Very scalable. Modular design allows systems to grow with cargo volumes, whether adding more vehicles, extending conveyors, or integrating additional zones.

Yes. Modular transport systems can be integrated into existing infrastructure with minimal disruption and are ideal for phased modernisation.

Automation reduces manual labour, increases speed and accuracy, improves safety, and enables 24/7 operation with consistent performance.

Yes. Intra terminal transport is fully connected to warehouse and terminal management systems, enabling smart routing, job assignment and performance monitoring.