ULD Storage

Safe & Scalable Storage for Unit Load Devices (ULDs)

ULD storage is vital for smooth cargo flows and operational reliability. As temporary buffer or long-term storage, it ensures that units are handled safely, space-efficiently and always in line with IATA standards. From floor-based setups to fully automated high-bay facilities, ULD storage solutions are tailored to terminal layout and throughput requirements.

Efficient ULD Storage for Any Terminal Size

Upon arrival from landside, build & break or the airside interface, ULDs are registered in the terminal management system and placed into storage. In manual setups, this means positioning them on ULD support pallets or castor decks, with location updates recorded in the system. In fully automated systems such as ETV or Lift & Run, storage and retrieval are system-guided, with ULDs automatically placed in racks and retrieved on demand for build-up, onward processing or aircraft loading.

In ULD storage, we combine four core strengths: products, software, system planning and service. Together, they deliver efficiency, compliance and future-ready performance – from simple manual racks to fully automated high-bay systems.

Key Benefits of Lödige’s ULD Storage Solutions

Focused on operational workflows, our process solutions create tangible benefits by streamlining handling steps, reducing turnaround times and enabling smooth coordination across all air cargo terminal areas.

Efficient and scalable storage options for every terminal

Air cargo terminals require flexible and reliable ULD storage. Depending on cargo volumes, available space, and automation level, different systems provide the right balance of capacity, efficiency, and investment. From simple manual setups to high-bay automated systems, Lödige offers the full range of ULD storage solutions.

Automation Levels for ULD Storage Solutions

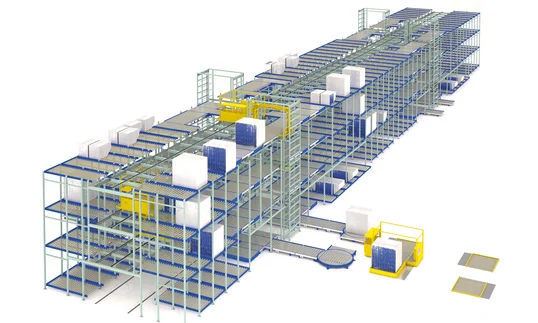

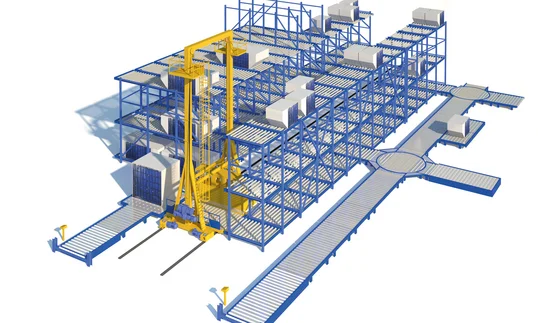

Lödige Industries offers a comprehensive range of ULD storage solutions for air cargo operations – from manual storage systems to highly automated Elevating Transfer Vehicle (ETV) and Lift & Run systems. Each product serves a specific role in ULD handling, providing varying degrees of automation, flexibility, scalability, and seamless integration into terminal operations.

Fully automated

Fully automated storage systems provide maximum efficiency and reliability for high-volume terminals. They are designed to optimise space, reduce manual handling, and ensure high throughput with full integration into the terminal control system. Functions include automated high-bay ULD storage, ULD tracking and storage optimisation, and SLA-based job execution.

Typical Equipment | Software Components |

|---|---|

| • Elevating Transfer Vehicle • Transfer Vehicle • Hoist • Storage Roller Deck • Powered Roller Deck • Multilevel racking • ULD cool room | Cargo Professional Suite (TMS) with Cargo Control and Cargo Direct Modules/ Functions: • ULD Control System • Live Operation Displays • Equipment Diagnostic System |

Semi-automated and mobile

Semi-automated storage systems combine structured layouts with improved handling efficiency. They are suitable for terminals that aim to increase throughput while keeping manual involvement for specific tasks. Functions include multilevel ULD storage with Lift & Run systems, semi-automated ETV solutions, and assisted empty ULD storage with hoists and non-powered decks.

Typical Equipment | Software Components |

| • FlexLoader • 2-level racking • Elevating Transfer Vehicle • Transfer Vehicle • Hoist • Storage Roller Deck • Powered Roller Deck • Multilevel racking • ULD cool room | Modules/ Functions: • ULD Control System (Inventory keeping) • Forklift guidance system |

Manual & Operator-Driven Systems

Manual storage systems provide maximum flexibility and are well-suited for terminals with moderate throughput and available floor space. ULDs are positioned on marked floor locations or basic support structures, with manual handling for empty and ground-level storage. Functions include ground-level storage at 203 mm or 508 mm as well as multilevel empty ULD storage using hoists with non-powered storage positions.

Typical Equipment | Software Components |

|---|---|

| • Castor Deck • Ball Deck • ULD Support Pallet • Non-powered storage decks with walkways | -- |

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Planning a new terminal or modernising your ULD storage?

Our experts are here to help.

Frequently Asked Questions (FAQs)

ULD storage refers to the temporary or long-term storage of empty or loaded Unit Load Devices (ULDs) within the terminal to ensure availability, traceability, and operational safety.

Storage options include ULD support pallets, castor decks, Lift & Run systems, and fully automated high-bay racking systems with ETVs or stacker cranes.

Yes. Manual storage on ULD Support Pallets or castor decks is ideal for smaller terminals, low-throughput areas, or as a flexible backup solution.

Automated systems use Elevating Transfer Vehicles (ETVs) or a combination of hoist and Transfer Vehicles to place ULDs into high-bay racks. These systems offer fast retrieval, high density, and full software integration.

Yes, all Lödige ULD storage systems are designed in accordance with IATA standards for safe and compliant ULD handling.

Each ULD is registered in the terminal management software and assigned a unique storage position, enabling real-time tracking and inventory control.

Typical transfer heights are 203 mm and 508 mm, matching standard equipment such as roller decks, slave pallets and AGVs.

Absolutely. All systems are modular and scalable, allowing for future capacity upgrades or automation enhancements.

Yes. Both manual and automated ULD storage solutions can be integrated into existing infrastructure with minimal disruption.

Yes. Lödige provides planning, upgrade and automation retrofit services to improve existing ULD storage areas for higher efficiency, extended lifecycle and increased throughput.