Reliable ULD Hoist for Efficient Air Cargo Handling

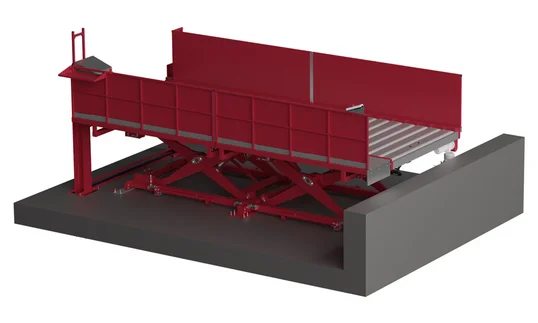

Facing bottlenecks in your air cargo operations due to inefficient ULD handling? The Lödige ULD Hoist provides an innovative, economical solution designed to enhance throughput in high-bay lift-and-run storage systems. This system combines vertical transport by the hoist with horizontal transfer by transfer vehicles (TV), allowing fast and efficient movement of ULDs across multiple storage levels within the terminal.

Streamline Your ULD Handling Processes

The Lödige ULD Hoist is a core component of lift-and-run storage systems, enabling rapid vertical transport of ULDs between levels. Equipped with a powered roller deck, the hoist ensures smooth cargo transfer. With features like automatic speed control, overload protection, safety doors, and an energy-efficient drive, it guarantees safe, reliable, and seamless operations.

Benefits of Lödige’s ULD Hoist

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The ULD Hoist comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

Key Features

- Fast, precise lifting and lowering of 5 ft, 10 ft and 15 ft ULDs

- Automatic speed control and soft stop at end positions

- Safety doors and overload detection for secure operation

- Integrated sensors for accurate ULD alignment

- Optional weighing system for efficient load control

- Energy-efficient AC drive with smooth acceleration and deceleration

Options

- Multi-hoist configuration for increased storage height

- Seamless integration into automated lift & run systems

- Safety doors for each access level

- Choice of steel or concrete shaft structure

Technical Data

Specification | 5ft for empty ULD | 5 ft | 10 ft WEP | 15 ft WEP | 20 ft NEP |

|---|---|---|---|---|---|

| Capacity | 200 kg | 1,600 kg | 6,800 kg | 6,800 kg | 13,600 kg |

| Length | 2,400 mm | 2,800 mm | 6,300 mm | 6,700 mm | 7,000 mm |

| Width | 2,600 mm | 2,500 mm | 2,900 mm | 2,900 mm | 7,200 mm |

| Elevation in top position | project-specific | ||||

| Elevation in lowest position | 508 mm | ||||

| Lifting speed | up to 1 m/s | ||||

| Acceleration | 1 m/s² | ||||

| Conveying speed | manual transfer | 0.3 m/s | |||

| Type of hoist | Counterweight system | ||||

Automation Degree

The Lödige ULD Hoist enables a high degree of automation in air cargo terminals. Integrated into the lift-and-run system, it automates vertical cargo movement between multiple levels while Transfer Vehicles handle horizontal transport. Combined with Lödige’s Cargo Professional Suite software, the system ensures smooth, fully automated processes from ULD intake to storage and retrieval.

Safety features, automatic positioning, and intelligent load detection minimize manual intervention, reduce errors, and maximize efficiency. This flexible automation concept supports both fully automated terminals and hybrid solutions, allowing step-by-step scalability to meet growing operational demands.

Tools & Downloads

-

Airport Logistics Solutions

Brochure

Hoists successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

At SATS Terminal 5 Singapore, the Lödige 15ft ULD Hoist ensures fast and reliable vertical transport of ULDs. Integrated in a highly automated lift-and-run system, it supports maximum throughput and efficient cargo handling.

At the Cargologic terminal at Zurich Airport, the Lödige 15ft ULD Hoist is a key part of the automated lift-and-run system. It ensures seamless vertical transport of ULDs, supporting high throughput and efficient cargo flows.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Boost vertical efficiency in your cargo terminal.

Talk to us about integrating the Lödige ULD Hoist into your terminal – for safe, space-saving and high-performance ULD storage.

FAQs

No. The system is designed for indoor use in air cargo terminals.

The standard roller deck operates at 508 mm transfer height.

Yes, the hoist platform is compatible with ULD Support Pallets, ensuring safe and guided transfer.

No pit is needed. The hoist operates within a steel or concrete shaft structure, standing directly on the floor.

Yes. Acceleration and deceleration are smooth and jerk-free. The system includes rubber buffers and emergency stop functions.

The system is designed specifically for empty 5 ft ULDs.

The hoist includes guide rails, position sensors, overload protection, and optional interlocked safety doors.

Yes. Its compact, modular design makes it suitable for upgrades or retrofits.

Very low maintenance – bearings are sealed and the structure is designed for long-term durability.