Integrating automated goods lifts with AGVs and AMRs

Automation of multi-storey transport processes with goods and freight lifts from Lödige Industries

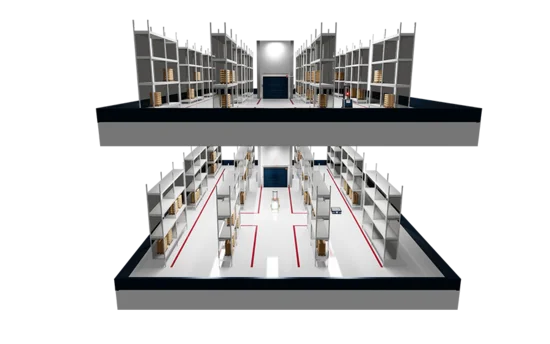

The lack of available land in densely populated areas and rising rental prices for warehouses are among the reasons for the rise of multi-storey warehouses. The automation module for Lödige goods and freight lifts optimises internal material transport for warehouses and production facilities and automates transport across multiple floors via automated guided vehicles (AGVs) and autonomous mobile robots (AMRs).

Benefits of automated goods lifts and AGVs/AMRs

How automated goods lifts operate with AMRs/AGVs

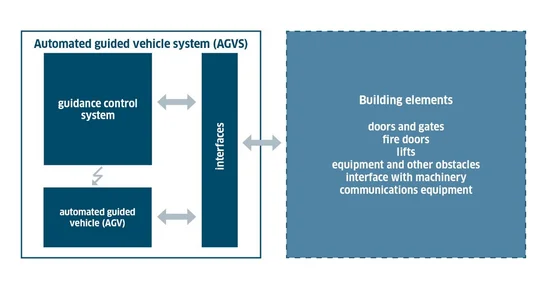

Automated goods lifts enable a variety of AGVs and AMRs to independently access multiple levels within a warehouse. The warehouse management system controls both, the AGVs/AMRs and the lift fully automatically including the opening and closing of the lift doors.

The AGV/AMR module for our goods lifts enables automated and, in mixed operation, optionally manual operation. Control takes place via potential-free contacts for the SHERPA goods lift or parameterised interface connection in combination with the OLYMPUS freight lift.

Increasing storage capacities with automated goods lifts - integration for new and existing buildings

The combination of intelligent freight lifts and AGV/AMR fleet enables operators of warehouses and manufacturing facilities to effectively link all storage space and automate it while maintaining the same floor space. Even if an AGV application is not planned immediately, it can make sense to have the goods lift already equipped for this application in order to avoid higher adaptation costs later.

Uninterrupted smoothly interlocking systems - how automated freight lifts improve your performance.

Avoid downtime and improve overall operations by automating vertical AGV/AMR transport in your warehouse or production facility. Using freight lifts to automatically transport your AGV or AMR fleet to other floors extends the automation of your facility to other floors. The walking distances of your staff and the transport processes are thus shortened. Staff no longer need to escort or send goods to other levels, reducing wasted time and prioritising higher value tasks.

Maximise the benefits of automation in an instant - save space, costs and time.

By installing a freight lift to transport your AGVs or AMRs to multiple levels, you can extend the benefits of mobile automation systems in no time. AGVs/AMRs are a flexible and easily scalable automation tool, which can further maximise the level of automation in your facility and improve your ROI anytime.

We can help you choose and plan your automated goods or freight lift

The robust SHERPA goods lift, suitable for loads up to 4500kg, optionally has its own shaft and can be easily integrated into new or existing buildings and racking systems.

The OLYMPUS goods lift transports goods up to 20t in weight and 30m lifting height, making it ideal for industrial production facilities and warehouses.

Possible applications of automated goods lifts

Production

A goods lift in combination with an AGV can automatically link different production steps, even across several levels. By using it, the entire production process can be optimised.

Warehouses

Warehouses can serve all levels in the storage area fully automatically by using an automatic goods lift in combination with an AGV. The simple and fast integration increases flexibility by enabling automated, mixed or optionally manual operation.

Technical details of our automated lifts

| SHERPA | OLYMPUS | |

| Doors/Gates | rolling doors | blade doors or lifting gates |

| Maximum load of the AGV/AMR | 1000kg* | 20t |

| Gap width | 20mm* | 5 model variants from 10 mm to 30 mm plus tolerances |

| Flooring | Base made of smooth sheet metal with 2K anti-slip coating | Various cabin floor options in plain sheet metal, steel, stainless steel |

| Operation | Mixed Operation | Mixed operation (Automatic/Manual) |

*Other options on request.

Ground clearance of the FTF/AGV is taken into consideration

When driving the FTF/AGV and AMR into the lift cabin, there may be a small difference in height between the car floor and the fixed floor of the respective floor (SHERPA) or between the lift shaft door and the car door (OLYMPUS) due to the weight of the vehicle plus the transported load.

Please inform us of the max. floor clearance of the FTF/AGV and AMR in your enquiry so that we can take this into account when designing the lift.

Frequently asked questions (FAQs)

There are a variety of options for the communication between lifts and fleet management systems. These range from hard-wired solutions to radio solutions.

The use of parameterised interfaces allows the implementation of any scenario. For example, opposite doors can be opened individually to allow the entry or exit of an AGV. In another scenario, both gates can be opened simultaneously to allow the passage of an AGV.

These functional interfaces between the lift and the AGV can for example establish and exchange the following information:

- Loading status of the AGV

- Identification of the loading equipment / transported goods (e.g. RFID or barcode)

- Contour control (control of the critical dimensions of the transport goods / loading equipment)

- Weight control

- Locking control (e.g. for roll containers or wire mesh boxes)

There are hundreds of different AGV and AMR models in all shapes and sizes. Rated load, roller or wheel arrangement and ground clearance are all critical factors in deciding whether a model is suitable for transport in an automated goods or freight lift.

Our goods lift experts will be happy to help you select the right lift. Get in touch now!

See more information and a selection of solutions that the SHERPA can transport here.

Depending on your needs, a SHERPA or OLYMPUS may be the right lift for you. The most important criteria include the weight of the load, as well as the lifting height. The size and heaviness of the load also affects the maximum car size, which also plays a role, along with the maximum rated load, minimum shaft pit dimensions and shaft head size.

You can find more information on this in our practical planning guide and in the white paper on the correct dimensioning of a goods or freight lift.In addition, our experts are always there to help you find the best solution.

Please contact us

We look forward to your message.