Optimise efficiency throughout your parcel handling and sortation

Improve your order accuracy, throughput and efficiency

The rise of e-commerce fulfilment and direct-to-consumer marketing, challenges conventional distribution centres to improve their picking, sorting and handling operations.

Our efficient parcel handling and sorting solutions:

- Goods Handling Solutions - Optimal operations and ergonomics plus real time data

- Sortation Solutions - Improve sorting efficiency and reduce labour costs

- Warehouse Management Solutions (WMS) - Deep data insights and powerful process control

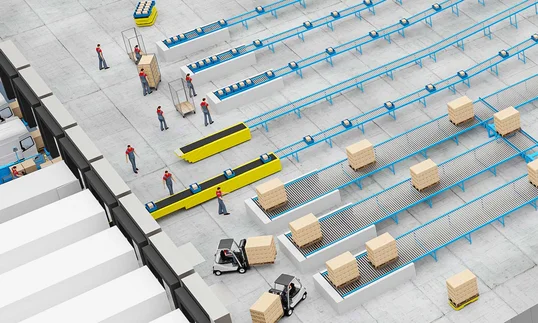

Our solutions are designed to keep automated parcel handling and sortation systems running smoothly, transforming a bulk flow of packages into a single-file stream and optimise picking and packing. Goods handling and sortation systems have a wide range of applications for the ourier, Express and Parcel industry (CEP) such as logistics, e-commerce, airports, pharmaceuticals and medical supply, food and beverages suppliers and others.

Automation allows companies to remain competitive by limiting their reliance on manual labour for repetitive tasks, improving productivity, accuracy and profitability. This efficiency, coupled with a low component count that aids maintenance, should help to reduce overall running costs.

Increase your throughput capacity

Benefit from handling and sortation solutions from Lödige Industries

Efficient parcel handling and sorting solutions from Lödige Industries

Goods Handling Solutions

Reduce order cycle time

Current global trends such as just-in-time, containerisation, and increased e-commerce order volumes have highlighted the capacity limitations of existing systems in hubs and distribution centres. Innovative material handling technology from Lödige Industries can be a game changer for optimising your operations, improving ergonomics for your workforce and applying real-time data capture for full inventory control and smart decision making.

Sorting Solutions

Efficient sorting without mistakes

Automated sorting systems move large volumes of material rapidly through distribution centres, allowing companies to export or import higher volumes with smaller storage space and lower labour costs. It allows retailers, e-commerce distributors, and postal service providers to handle the unprecedented package volumes more efficiently with a properly spaced stream of product.

From simple diverters and pushers to sophisticated high-speed crossbelt sorters, we can help you find the optimal automated sorting solution to meet your operational requirements.

Warehouse Management Solutions (WMS)

Track your material flow in real time

Benefits of Software & Integrated Controls

- Storage and slotting – Software analysis helps determine which items are picked more often and recommends their storage in more accessible locations.

- Accuracy - By keeping track of all materials and products in a facility and throughout a supply chain, software improves inventory and location accuracy.

- Lowering labor costs - Directing workers to tasks by priority and monitoring productivity for benchmarking, performance improvement and incentives.

- Process flow & Increased productivity – Software directs the right components to the correct production line, pick location or packing station as needed. The sequenced activities enable the most efficient method for completing each task, such as grouping orders to reduce travel and allowing workers to pick more orders in less time.

Want to upgrade your existing facility?

Or do you need support with the maintenance of your system or a system health check?

Find out more about our Services

Parcel Handling & Sortation Solutions by Lödige Industries

Enabling our customers to achieve their goals

Looking for more?

Please contact us

We look forward to your message.