Truck Dock - Efficient Air Cargo Loading Solution

Are you experiencing delays and safety concerns during the loading and unloading of air cargo? The Truck Dock by Lödige ensures smooth and safe transfers between trucks and cargo terminals, reducing handling times and improving workplace safety.

Precision ULD Handling

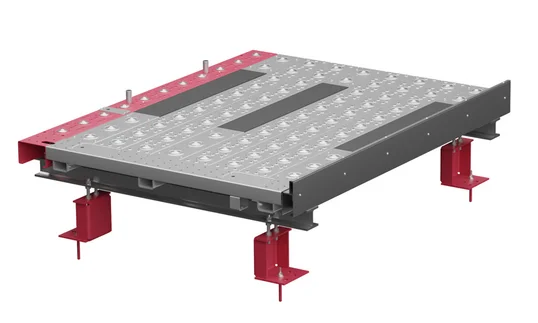

The Lödige Truck Dock efficiently facilitates the loading and unloading of ULDs using powered roller conveyors and a robust hydraulic lifting system. Available in various sizes (10ft, 15ft, 20ft), it seamlessly aligns with truck ramps and can integrate with manual or automated systems. Key features include safety skirts, an adjustable vertical shift, and optional weighing systems, ensuring compatibility with multiple ULD sizes and compliance with IATA standards.

Benefits of Lödige’s Truck Dock

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Truck Dock comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- 10 ft, 15 ft and 20 ft Truck Dock

- Integrated scale

- Side-shift function

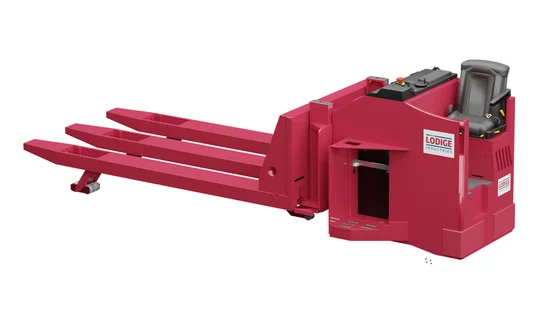

- Operator’s cabin

- Painted/Galvanised finishes

- Integrated winch for pulling ULD out of the truck

Technical Data

Description | 10 ft | 15 ft | 20 ft |

|---|---|---|---|

| Capacity | 6,800 kg | 6,800 kg | 13,600 kg |

| Length | 3,600 mm | 5,400 mm | 2 x 3,600 mm |

| Deck width | 2,700 mm | ||

| Deck orientation | Narrow Edge (NEP) | ||

| Conveying speed | 0.3 m/s | ||

| Elevation in lowest position | 508 mm | ||

| Elevation in top position | 1,808 mm | ||

| Lifting Stroke | 1,300 mm | ||

| Lifting speed | 0.05 m/s | ||

Automation Degree

Truck Docks are semi-automated, electro-hydraulic units designed for efficient, safe and controlled ULD transfers between lorries and internal terminal handling equipment. Fully integrated into the Cargo Professional Suite, they support real-time coordination and seamless cargo flows, ensuring reliable, IATA-compliant operations across landside interfaces.

Tools & Downloads

-

Air Cargo Terminal Equipment

Brochure, (07-2025)

Truck Docks successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

The new COOL Nordic cargo hub at Helsinki Airport, known in the industry as the "COOL Terminal" is the most modern air cargo terminal in Europe and one of the newest air freight hubs in the world.

Asia Airfreight Terminal optimises air cargo operations using six robust Lödige Truck Docks, significantly enhancing loading efficiency, safety, and turnaround times for high-volume freight handling.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

FAQs

Capacities range from 6,800 kg (10ft) to 13,600 kg (20ft). Dimensions vary accordingly.

Yes, it integrates easily into both manual and automated systems.

Yes, it supports flexible handling of 5ft, 10ft, 15ft, and 20ft ULDs.

It features safety trip bars, protective skirts, and secure controls, preventing accidents and ensuring operator safety.

Yes, an optional weighing facility is available, providing accurate load measurements.

Minimal maintenance is needed due to robust construction and design; routine checks ensure optimal operation.

Yes, it fully complies with IATA ULD Care regulations.

Yes, it includes fallback systems enabling manual operation.

Available Surface finishing include painted or galvanized coatings for durability in various environments.

Yes, additional options include operator platforms, winches, automatic levelling systems, and more.

Yes, it integrates seamlessly with sectional doors and traffic management systems.

It is used by ground handling planners, air cargo service providers, logistics consultants, and cargo terminal operators globally.