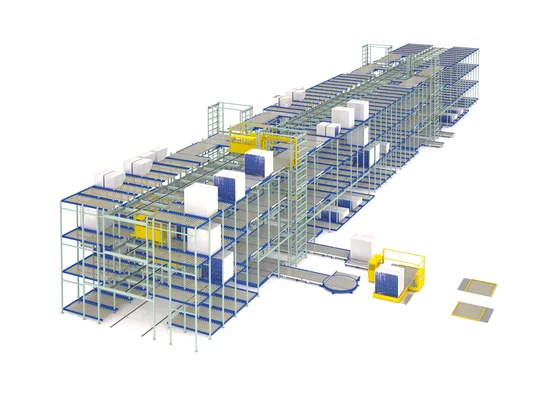

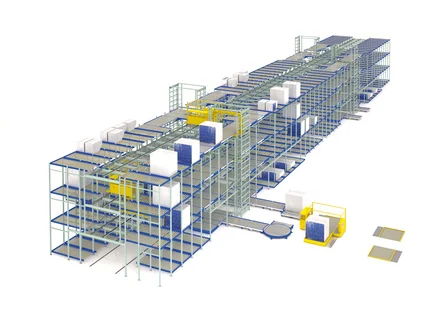

Lift & Run Storage Systems for ULDs

ULD storage for maximum space efficiency and throughput

High ULD volumes, limited floor space and time-critical processes are key challenges in modern cargo terminals. Lift & Run systems provide scalable multi-level storage using a combination of hoists and transfer vehicles. This design ensures fast access to each position, short transfer times and reliable performance – making it the ideal choice for terminals aiming to optimise capacity and efficiency.

What Lift & Run ULD Storage Does

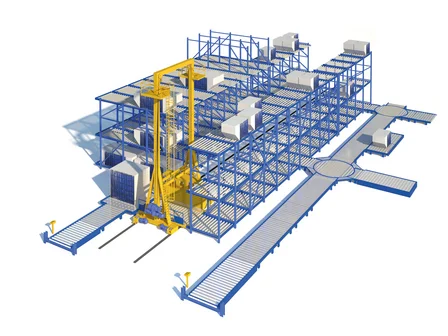

Lift & Run systems store Unit Load Devices (ULDs) in multi-level racking structures, with storage decks for each position. Hoists handle the vertical movement of ULDs, while transfer vehicles manage the horizontal transport within the system. This separation of vertical and horizontal movement allows multiple vehicles to operate in parallel, reducing waiting times and enabling high throughput. The result: scalable storage with fast access to any position, even under peak load.

Benefits of Lödige’s Lift & Run Storage Systems

Focused on space utilisation and handling efficiency, our storage solutions deliver measurable benefits by optimising capacity, ensuring safe ULD handling and enabling seamless integration with terminal workflows.

What is the difference between ETV and Lift & Run storages?

Both ETV and Lift & Run systems offer fully automated, high-performance ULD storage designed for large-scale cargo terminals. ETV storage systems combine vertical and horizontal movements in one vehicle, making them a proven choice for long high-bay aisles and maximum use of vertical space. Lift & Run systems, by contrast, separate lifting and transfer into dedicated units that work in parallel, giving faster access to storage positions and high flexibility under peak loads.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Plan your next step in ULD storage.

Talk to our experts to find the right solution – from manual setups to fully automated systems.

Frequently Asked Questions (FAQs)

This depends on the number of levels and lanes. Systems range from dozens to hundreds of ULD positions.

Yes. The system supports 5ft, 10ft and 15ft ULDs depending on configuration.

With simultaneous vertical and horizontal movement, retrieval can be completed in less than 60 seconds per unit (typical layout).

Yes, it is suitable for integration into +2°C to +25°C environments with insulated doors and racks.

Yes. The system integrates seamlessly with Lödige’s Cargo Professional Suite and can be linked to external WMS or airport systems.