ULD Support Pallets – Flexible Handling & Storage of ULDs

(former Slave Pallets)

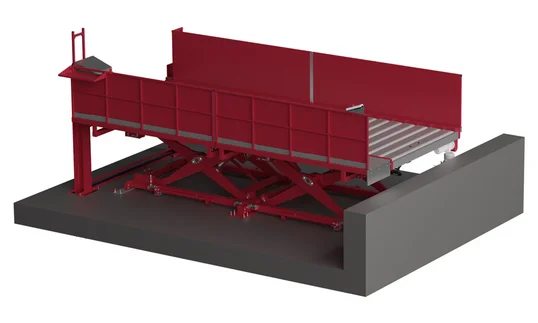

Fully IATA-compliant and designed for safe ULD processing, Lödige ULD Support Pallets offer a robust and modular solution for storing and moving ULDs in air cargo terminals. They support ergonomic build & break, temporary staging, and seamless transfer at the airside interface.

Essential tool for handling and transporting ULDs on a flexible way.

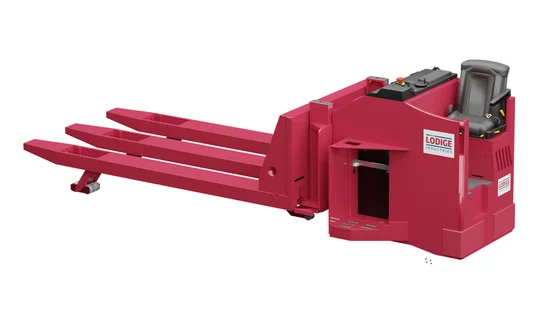

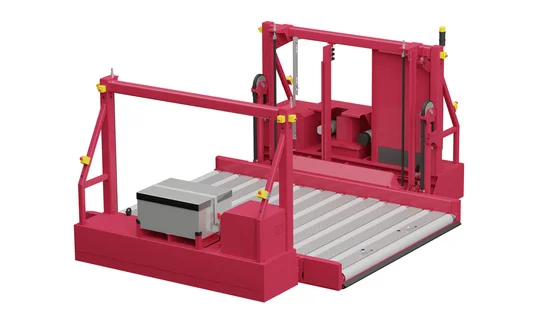

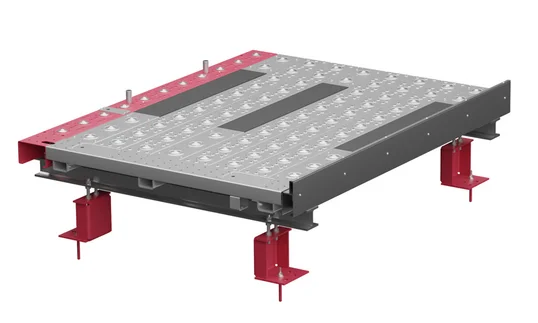

Lödige ULD Support Pallets are designed to hold ULDs (up to 6,800 kg) safely at standardised system heights of 203 mm or 508 mm. Each pallet ensures IATA-compliant four-sided access and includes fixed side guides for proper ULD alignment. The Cargo Pallet Mover is used to lift and move these pallets safely within the terminal.

Benefits of Lödige’s ULD Support Pallet

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The ULD Support Pallet comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features & Options

- 5ft, 10 ft NEP, 10 ft WEP & 10 ft Ball

- Hot-dip galvanized

- Safety finger stops (manual)

- Stackable

- Optional forktine pockets

Technical Data

Description | 5ft | 10 ft NEP | 10 ft WEP | 10 ft ball |

| Length | 2000 mm | 3300 mm | 3350 mm | 3300 mm |

| Width | 2000 mm | 2550 mm | 2600 mm | 2550 mm |

| Capacity | 1,600 kg | 6,800 kg | ||

| Dead weight | - | ∼650 kg | ||

| Lowest transfer height | 203 mm | |||

| Free height for forks | 128 mm | |||

| Type of stops | Safety finger stops (manual) | |||

Tools & Downloads

-

Air Cargo Terminal Equipment

Brochure, (07-2025)

ULD Support Pallets successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

The new COOL Nordic cargo hub at Helsinki Airport, known in the industry as the "COOL Terminal" is the most modern air cargo terminal in Europe and one of the newest air freight hubs in the world.

Lödige’s flexible approach ensured SCSC achieved the functionality and capability needed to create a world class facility.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Related Products

Discover Solutions for Consignment Handling

Explore related products that make consignment handling more efficient, compliant and scalable. Each solution contributes to secure storage, reliable processes and seamless integration into your terminal setup.

FAQs

Yes. The galvanized steel construction and non-slip surface make it suitable for perishable environments and cool rooms.

To date, there are no plans to transfer AGV to Support Pallet.

It handles up to 15 ft ULDs in NEP or WEP orientation with a capacity of 6,800 kg.

Yes, when not in use, they can be stacked to save floor space.

Yes. Integrated roller beds and manual stops make it ideal for secure build-up and breakdown operations.

Yes. Multiple ULD Support Pallets can be aligned to form a manual handling lane at standard interface height.

Standard is hot dip galvanised, optional colour.

Yes. A non-slip tread plate ensures safety during manual loading and inspection tasks.

They serve as a flexible base element and integrate easily with roller decks, workstations, dollies, and manual storage zones.