German online retailer improves its distribution centre performance

Lödige Industries equips distribution centre with 12 goods lifts in 3 years

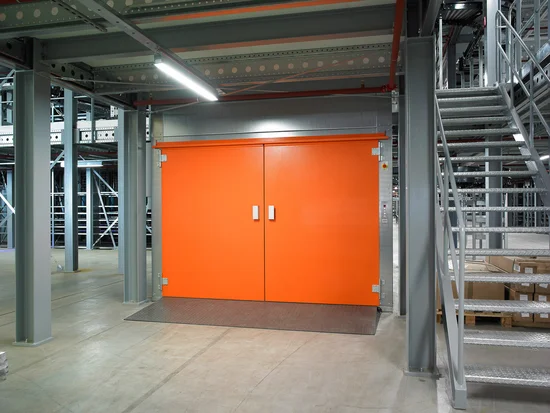

Over a period of three years, Lödige Industries has delivered 12 SHERPA goods lifts to a newly built distribution centre in use of a German online retailer. The customer required a solution which would guarantee high throughput and availability together with compact construction. After installing nine SHERPA goods lifts in 2013, the customer decided to install two more SHERPA in 2015 and one in 2016.

How does the customer benefit from relying on SHERPA goods lifts?

Save space

The customer needed a compact lifting solution. Altogether four different elevator sizes were installed for this customer. The sizes fit the different pallets and picking trolleys, which the customer is using. Additional space was gained by reducing the floor space of some SHERPA freight elevators. Pallets and picking trolleys are moved efficiently and without disturbances between levels.

Structural conditions do not complicate the installation of the SHERPA as the motor is located in the head room. Moreover, the control cabinet can be positioned remotly from the lift. Access for maintenance is provided via a maintenance gap above the upper door to the shaft head room. The area around the lifts can thus be used for other purposes.

Flexible integration

12 SHERPA goods lifts in total had to be optimally positioned. The foundations of the hall supports and the hall ceiling girders had to be taken into account. The Lödige SHERPA comes with a free-standing shaft structure and hence it does not require any rack modifications. By using 80 mm high ramps, it was possible to dispense with shaft pits for the SHERPA freight elevators. As a result, the freight elevators could be optimally positioned without any structural changes, thus achieving a high degree of flexibility for integration into the racking systems.

High throughput

More importantly, the customer required a solution that offers a high throughput. Usually, goods lifts have a transportation speed of 0,2m/s. The 12 SHERPA goods lifts at this project offer a maximum transportation speed of 0,4m/s. This means, the lifting frequency for the customer was doubled.

Facts and figures

Challenges for the online retailer in doubling frequency

- Taking structural conditions of the existing rack warehouse into account, as no change to the racks and building itself can be made

- Transport of pallets and picking trolleys in different sizes

- Different lifting capacities and lifting heights necessary

- Increasing throughput of goods over several levels of the rack warehouse

Solution from Lödige and benefits for the customer

- SHERPA goods lifts come with a free-standing shaft and no need for a pit

- Compact construction by installing goods lifts in two customized sizes, lifting capacities and heights

- Doubled lifting speed of 0.4 m/s leading to high throughput