Landside Interface

Handling solutions for fast and transparent cargo acceptance and delivery

The landside interface is where cargo enters or exits the terminal by truck, van or container. As the link between road transport and terminal operations, it is crucial for smooth cargo flows. Structured acceptance procedures, whether manual or digital, help reduce waiting times, improve traceability and avoid bottlenecks.

The Landside Interface Process

At the landside interface, trucks deliver export freight to the terminal. Euro pallets, ULDs and loose cargo are unloaded, verified and routed to storage or directly to build-up. For import freight, shipments processed in the build & break area are prepared for truck loading. They can be dispatched as pallets for local distribution or continue as complete ULDs via Road Feeder Services (RFS) to other airports. Handling methods vary by cargo type – for example, forklifts are used for pallets and truck docks for ULDs.

At the landside interface, we bring together our four core competencies: products, software, system planning and service. Combined, they form the foundation for smooth truck handling, fast acceptance and delivery processes, and scalable performance to meet growing cargo volumes.

Benefits of Lödige's Landside Interface Solutions

Focused on operational workflows, our process solutions create tangible benefits by streamlining handling steps, reducing turnaround times and enabling smooth coordination across all air cargo terminal areas.

Levels of Automation

From manual acceptance to fully integrated terminal processes

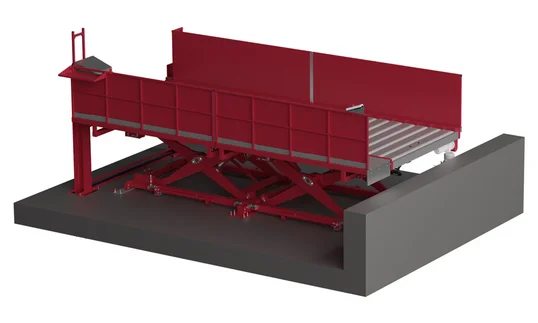

Landside interface systems can be implemented at different levels of automation to suit operational demands, infrastructure layout, and cargo volumes. From basic forklift unloading to fully automated truck docks with integrated scanning, each level helps streamline handover processes between the road and the terminal.

Fully automated

Fully automated landside systems are designed for high-throughput terminals. ULDs are unloaded using integrated docks with automatic scanning, weighing and identification. The system assigns docks, monitors SLA timeframes and tracks cargo through all stages of arrival. Storage jobs are executed automatically, while consignments are processed via smart check-in with integrated identification, volume measurement and weighing.

Typical Equipment | Software Components |

|---|---|

| ULD: Integrated Truck Docks with weighing and identification system with adjacent fully automated • ULD Roller decks • ULD Right-angle Deck • ULD Turntable • ULD AGV | Cargo Professional Suite (TMS) Modules/ Functions: |

| Consignment: • Smart Gate (weighing, volume analysis, identification of consignments) |

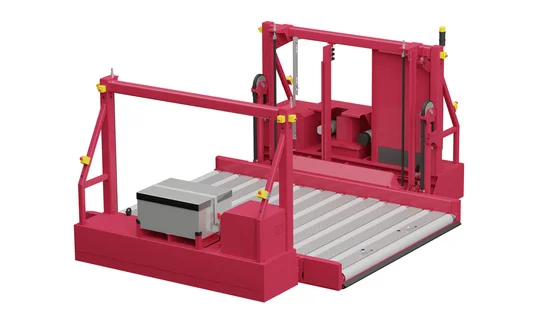

Semi-automated and mobile

Semi-automated landside solutions reduce manual labour through powered equipment and guided processes. Typical functions include semi-automated ULD truck (un)loading, guided transfer of in-house pallets with consignment goods from truck door to temporary storage or other areas, and consignment check-in with identification, volume measurement and weighing. FlexLoaders and powered roller decks support ergonomic cargo transfer, while software modules enable partial job tracking.

Typical Equipment | Software Components |

|---|---|

| ULD: • Truck dock | Cargo Professional Suite (TMS) Modules/ Functions: |

| Consignment: • Inhouse Pallets • Barcode / QR-Code Scanners • Forklifts equipped with Forklift Guidance Screen • X-Ray • Floor scales • Stationary volume analyzer |

Manual & Operator-Driven Systems

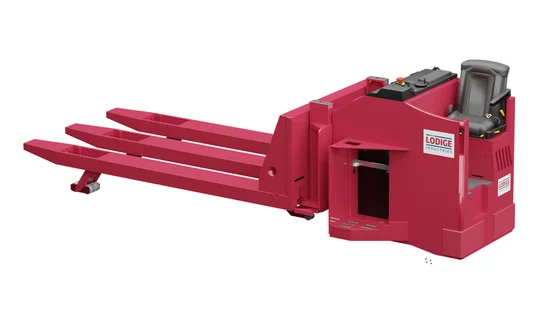

Manual systems provide a flexible baseline solution for basic operations. ULDs are moved on support pallets with Cargo Pallet Movers, while consignments are handled with in-house pallets and forklifts. Functions include manual ULD truck (un)loading, consignment check-in, and direct transfer to storage or processing zones. Safety checks, weighing, and special cargo handling (OOG, DGR) are also performed manually.

Typical Equipment | Software Components |

| ULD: • FlexLoader • Truck dock • Cargo Pallet Mover for truck dock connection • ULD Support Pallet | Cargo Professional Suite (TMS) Modules/ Functions: |

| Consignment: • Forklifts • Inhouse Pallets • Barcode / QR-Code Sanners • X-Ray • Floor scales • Stationary volume analyser |

Discover Solutions for Landside Interface

Discover equipment that supports efficient truck handling and consignment acceptance. From docks to weighing and screening, these products ensure smooth integration into your landside processes.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Need support with landside planning or modernisation?

Our experts are here to help.

Frequently Asked Questions (FAQs)

The landside interface is the operational zone where cargo is accepted from or delivered to trucks and other road vehicles. It connects the external transport network with internal terminal processes.

Incoming cargo is scanned, registered in the terminal system, and prepared for storage or build-up. Optional steps include weighing, X-ray, or special handling checks.

Export shipments arrive by truck and are processed according to their type. Standard freight may be placed on inhouse pallets or directly consolidated into ULDs, while special cargo such as oversized or dangerous goods follows dedicated handling procedures. All shipments are documented, weighed and released for further processing, which may include build & break workstations, storage systems, or direct transfer to the airside interface.

On import, shipments arriving from the airside are prepared for onward distribution by truck. ULDs, Euro pallets or loose cargo are transferred from storage or breakdown areas to the landside, where they are documented, weighed and released. Depending on cargo type, handling may involve forklifts for pallets or truck docks for ULDs. From there, the cargo exits the terminal and continues its journey via road transport.

Yes. Automated gates, dock management systems, and mobile scanning devices streamline check-in, cargo registration, and process routing for greater efficiency.

All shipments are scanned and logged into the terminal system, with location and process status tracked in real time. Integration with WMS or TMS enables full transparency.

The system handles general cargo, palletised freight, loose consignments, and special cargo types such as dangerous goods (DGR), pharmaceuticals or OOG shipments.

Lödige systems enable efficient slot management, buffer zones, and prioritisation rules to optimise throughput and minimise bottlenecks during peak times.

Yes. Interfaces with customs clearance, X-ray systems, and security checks are fully supported and can be integrated into the process flow.

Absolutely. Lödige provides planning, upgrades, and modernisation services to improve landside layouts, workflows, and IT integration.