Optimal Connection between Terminal and Apron

Increase the speed and safety of ULD transfers between terminal and apron without additional infrastructure. The Tilting Roller Deck facilitates rapid and precise handovers of ULDs, compensating for height differences and reducing transfer resistance. This minimises downtime and transport damage.

Efficient ULD Transfer with Precision Tilt Technology

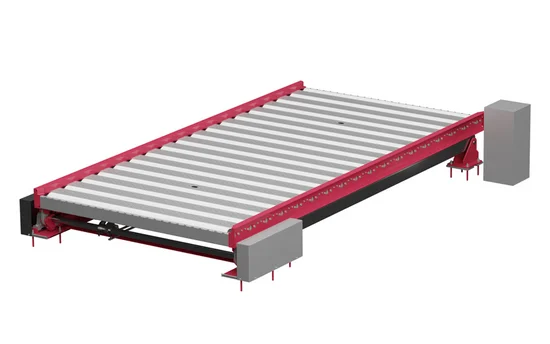

The Lödige Tilting Roller Deck is motorised equipment designed for efficient transfer of up to 15 ft ULDs in Narrow Edge Presenting (NEP) orientation. It features an eccentric cam system for precise ±50 mm tilt movements, compensating for height variations and reducing resistance during transfer to dollies. The system supports loads of up to 6,800 kg and operates at a standardised transfer height of 508 mm with conveyor speeds up to 18 m/min.

Benefits of Lödige’s Tilting Deck

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Tilting Roller Deck comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Technical Data

Description | |

| Capacity | 6,800 kg |

| Length | 5,100 mm |

| Width | 2,700 mm |

| Deck orientation | Narrow Edge (NEP) |

| Conveying speed | 0.3 m/s |

Tilting Function | |

| Type of action | Hydraulic |

| Amount of tilting function | ± 50 mm |

Automation Degree

Tilting Roller Decks compensate for height differences between terminal and dolly trains. Equipped with powered rollers, a hydraulic tilt function and integrated sensors, they operate semi-automatically to ensure fast and safe transfers. At the same time, fallback devices allow manual handling whenever required.

Tilting Decks provide a medium level of automation – delivering higher efficiency and safety than manual solutions while retaining flexibility through manual override.

Tools & Downloads

-

Flughafenlogistik

Broschüre (Englisch)

Tilting Decks successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

The new COOL Nordic cargo hub at Helsinki Airport, known in the industry as the "COOL Terminal" is the most modern air cargo terminal in Europe and one of the newest air freight hubs in the world.

At Turkish Cargo's state-of-the-art facility in Istanbul, Lödige Tilting Roller Decks ensure fast, safe, and efficient transfers of ULDs between terminal and dolly trains. Thanks to precise tilt technology and robust construction, these decks significantly reduce handling time, minimise cargo damage, and support peak operational standards.

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

FAQs

Up to 6,800 kg for 15-ft ULDs.

A standardized transfer height of 508 mm.

Yes, the drive can be disengaged via a clutch for manual operation.

Tilt movement is achieved through an eccentric cam system with integrated sensors for exact positioning.

Non-slip surfaces, integrated sensors, and safety controls ensure safe operation.

Yes, galvanized materials ensure weather resistance.

Up to 18 m/min for efficient processes.

Yes, fully integrable with the Terminal Management System, enabling reliable process control, real-time tracking, and scalability through Lödige’s Cargo Professional Suite.

Easy maintenance thanks to removable, galvanized walkways for quick servicing.

Yes, it meets all relevant IATA standards for ULD handling.

Multiple international air cargo terminals rely on Lödige Tilting Roller Decks.