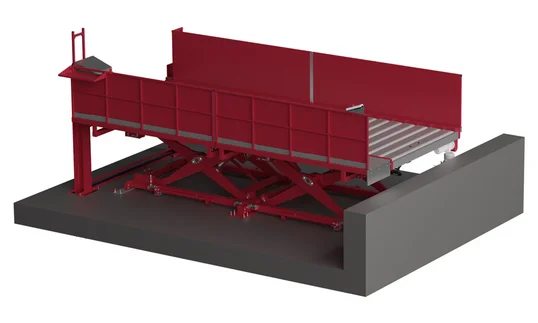

Powered Roller Deck – Precise ULD Handling for Efficient Terminal Operations

Fast, safe and reliable ULD transport is essential for smooth terminal logistics. Whether at truck docks, racking, build & break zones or airside interfaces – powered roller decks ensure accurate ULD positioning and seamless integration with automated and semi-automated handling systems. A perfect fit for terminals requiring scalable, high-performance infrastructure.

Modular Powered Roller Decks for High-Throughput ULD Transport

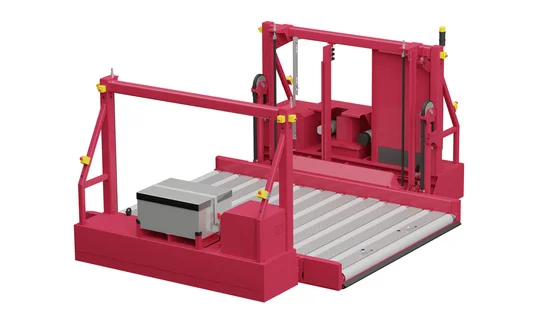

Lödige Powered Roller Decks are motor-driven modules for transporting and storing ULDs in cargo terminals. Used in racking systems, truck docks, airside and build & break areas, they ensure precise positioning and controlled movement of 5 ft, 10 ft or 15 ft ULDs. Integrated brakes hold ULDs safely in place; optional features like built-in scales, pop-up balls for 90° transfer or fork tine pockets enhance system flexibility.

Benefits of Lödige’s Powered Roller Deck

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Powered Roller Deck comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- Additional Roller:

Deck length can be varied by 300mm per roller. The load capacity of 1,600 / 6,800 kg does NOT increase. - Galvanised Roller Deck:

Frame, fixings and rollers can be galvanised on request. - Powered Stop:

Powered Stops can be included position ULDs at the end of a roller deck lane. - Weighing Facility:

The weighing system is provided by load cells incorporated into the decks. Live load capacity is 6,800 kg minimum per 10ft section.

The mechanism can withstand all forces experienced through ULD transfer, for example braking of transfer operation or hitting stops, without being adversely affected. Read out variation is not produced by different positioning of the load centre of gravity. The load measuring devices are sealed and shielded to prevent interference from other electrical equipment in the area.

Technical Data

Description | 5 ft | 10 ft NEP | 10 ft WEP |

|---|---|---|---|

| Capacity | 1,600 kg | 6,800 kg | 6,800 kg |

| Length | 2,500 mm | 3,600 mm | 2,700 mm |

| Width | 1,800 mm | 2,700 mm | 3,500 mm |

| Transfer height | 508 mm | ||

| Conveying speed | 0.3 m/s | ||

Automation Degree

Powered Roller Decks are semi-automated modules with integrated electric drives for controlled ULD movement. While not autonomous, they can be fully integrated into warehouse management systems (WMS) and the Lödige Cargo Professional Suite for coordinated operation and process monitoring. Ideal for use in automated racking, build & break zones, and airside interfaces. Optional features such as pop-up balls or integrated scales increase automation flexibility.

Tools & Downloads

-

Air Cargo Terminal Equipment

Brochure, (07-2025)

Powered Roller Decks successfully in operation

Proven in practice, our solutions demonstrate their value worldwide every day.

In Helsinki, Powered Roller Decks ensure reliable ULD flow within Finnair Cargo’s fully automated high-bay warehouse and build & break zones.

At the Istanbul hub, Lödige Powered Roller Decks support automated ULD transport between storage, airside and processing zones—designed for high throughput and 24/7 operation.

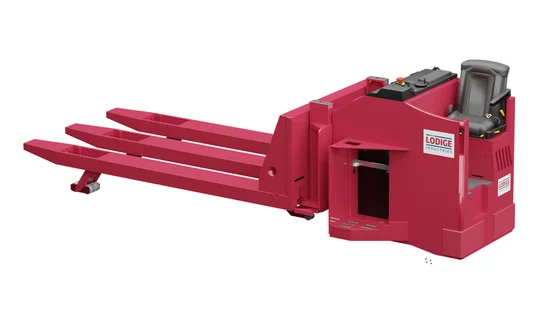

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Planning or upgrading internal transport?

Our experts are ready to support.

FAQs

Standard load capacity is 6,800 kg for 10ft decks and 1,600 kg for 5ft decks.

Transfer speed is 18 m/min for all deck sizes.

Yes, decks are available for Narrow Edge Presenting (NEP) and Wide Edge Presenting (WEP) configurations.

No, the deck operates at standard heights (203 mm or 508 mm) without a pit.

Yes, the drive can be disengaged via the clutch for manual ULD movement.

Absolutely, all Powered Roller Decks meet IATA ULD handling standards.

Yes, optional hydraulic or pneumatic pop-up balls enable direction change or 360° rotation, especially useful for 5ft ULDs.

Yes, with galvanized finish, the decks are suitable for cold rooms, perishable zones, and apron use.

Yes, integrated load cells are available for precise weight verification during build & break and import/export handling.

Powered Roller Decks are ideal wherever ULDs need to be transported automatically within the terminal. This includes internal transport routes, build & break areas, airside interfaces, and automated ULD storage systems. Their modular design allows seamless integration into both new and existing cargo handling environments.