Renewable energies and energy efficiency measures

The foundation for sustainable production was laid back in 1965, when the family business, founded in Paderborn in 1948, relocated its production to Scherfelde. On the site of a former wool factory, a hydroelectric power plant on the nearby Diemel River has since provided us with a continuous supply of renewable energy, which forms the basis of our electricity production thanks to ongoing modernization, maintenance, and care. Since 2020, our green electricity has also been produced by our own solar park. In 2024, 1,500,000 kilowatt hours of renewable energy were generated.

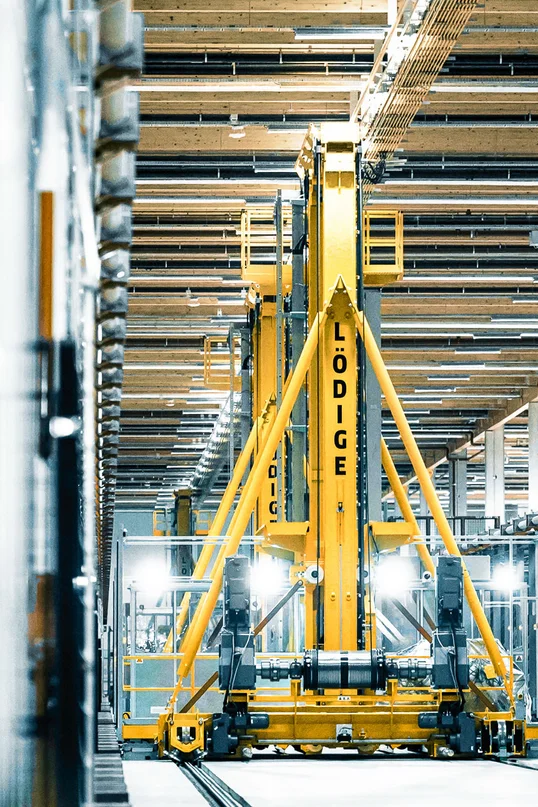

Location Scherfede, Germany

A look into the future

We will continue to focus consistently on innovation and sustainability in the future. That is why we are planning a gradual conversion of the heating system in our production halls, including the use of heat pumps and waste heat. In addition, we are examining measures to optimize our compressed air system in order to tap further potential for efficiency in energy consumption.

Location Brasov, Romania

ISO 14001 Certificates

We are proud that 11 Lödige Industries companies have now been certified according to ISO 14001. This certification confirms our consistent commitment to effective environmental management and the sustainable development of our processes worldwide. It is an expression of our responsibility for environmental protection and our high standards in this area.