Coolrooms for Temperature-Controlled Air Cargo

Ensure precise temperature conditions for sensitive air cargo

Goods such as pharmaceuticals, perishables and other temperature-sensitive shipments require consistently stable and accurately controlled environments. Our Cool Rooms provide reliable temperature regulation, safeguarding your valuable cargo and ensuring compliance with international quality standards.

Temperature-Controlled ULD Storage with Integrated Rack Design

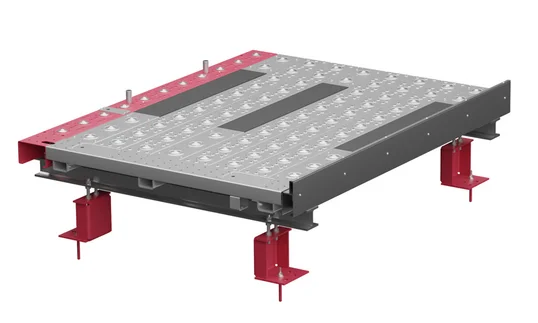

Lödige Coolrooms are climate-controlled chambers built directly into the ULD storage rack. Available as single- or two-level solutions, each room holds multiple 10 ft or 20 ft ULDs. Every zone can be configured independently, ensuring stable temperatures from +2 °C to +25 °C. Access is secured with sectional and hinged doors, and integration into ETV or TV aisles ensures seamless loading via friction-powered storage decks.

Benefits of Lödige’s Cool Room

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Built for High-Value and Sensitive Goods

Lödige Coolrooms are used for storing ULDs containing pharmaceutical products, fresh produce, or other temperature-critical shipments. The integration into your ULD storage racks reduces unnecessary movements and ensures safe, energy-efficient storage – all within IATA standards.

Technical Data

Description | |

| Temperature Range | +2 up to +25 °C |

| ULD size | up to 20 ft |

Insulation Panels | |

| Panel thickness (approx.) | 100 mm |

| Panel type | PIR Sandwich |

| Surface | white, food safe plastic laminated to galvanised steel sheet |

Doors | |

| Maintenance access | normal entry/exit door, unlockable from inside |

| Fast door type | Rapid Roll - PVC curtain |

| Clear width | 3,000 mm |

| Clear height (approx.) | 3,700 / 2,400 mm |

Automation Degree

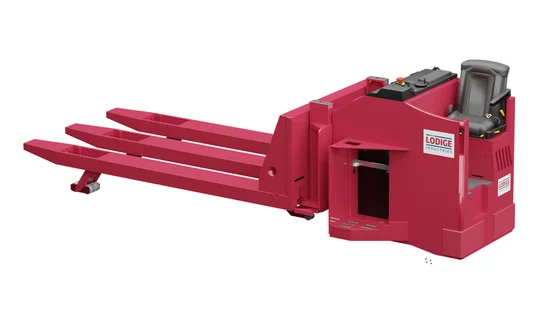

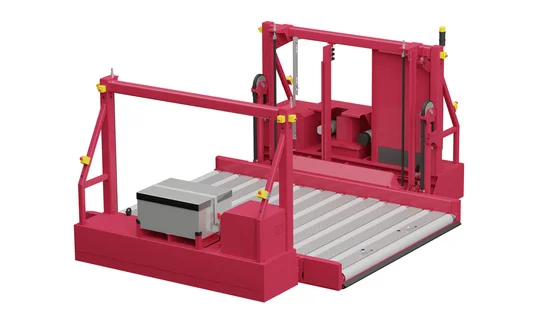

Lödige Cool Rooms support varying levels of automation. They can be accessed manually with forklifts, Cargo Pallet Movers, FlexLoaders or Castor and Ball Decks, using standalone temperature controls. Semi-automated setups link to friction-powered storage decks and terminal systems, with temperature control via EDS.

Fully automated solutions integrate Transfer Vehicles, Elevating Transfer Vehicles or roller conveyors with the Lödige Cargo Professional Suite, providing seamless connection to warehouse management and automation systems for hands-free loading, unloading and storage. This scalability allows operators to adapt from manual retrofits to high-throughput automated systems.

Tools & Downloads

-

Airport Logistics Solutions

Brochure (07-2025)

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Ready to optimise your temperature-controlled cargo handling?

Talk to our experts about tailored cool room solutions for safe, compliant and efficient ULD storage.

Frequently Asked Questions (FAQs)

Each room can be individually set between +2 °C and +25 °C. Common presets include +2 to +8 °C (COL) and +15 to +25 °C (CRT).

Coolrooms are embedded into the ULD storage rack, accessible via the ETV or TV aisle. Each lane uses standard Storage Decks.

Sectional doors include manual overrides; hinged doors have inside-opening mechanisms. All systems meet safety standards.

Yes. Lödige Coolrooms meet the temperature stability and documentation requirements for pharmaceutical goods storage.

Yes. Temperature settings and operational status can be viewed and controlled via EDS and WMS integration.

Sandwich panels with PIR sandwich panel insulation and coated steel sheets.

Yes. Each room operates independently.

Access via sectional doors from the ETV/TV aisle and hinged personnel doors from the terminal side.

Yes. Supports fully automated storage and retrieval operations.