Automated Storage System Powers HK Electric’s Safe and Efficient Cable Drum Handling

Four‑level ETV system maximizes storage capacity and improves inventory control at HK Electric in Hong Kong

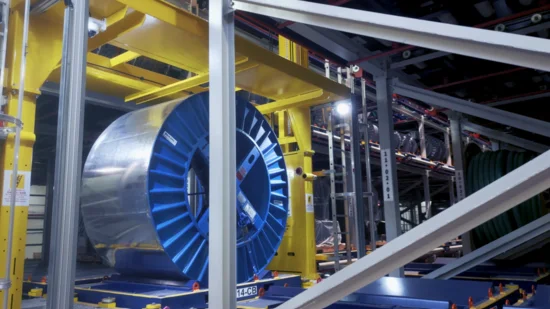

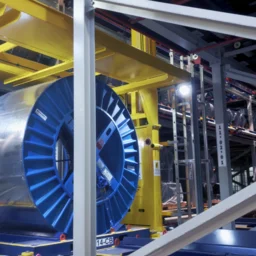

To support the reliable electricity supply of Hong Kong and Lamma islands, The Hongkong Electric Co., Ltd. (HK Electric) has modernised its cable drum storage with an automated solution from Lödige Industries. Installed at the company’s Electric Tower facility in Ap Lei Chau, this project marks a significant step in applying advanced intralogistics technology to the energy sector.

Faced with space constraints and increasing inventory demand, HK Electric required a compact, automated system to store and track large and heavy cable drums—each weighing more than five tonnes—without compromising safety or accessibility. Manual handling had become physically demanding and prone to inefficiencies, intensifying the need for a robust warehouse automation solution.

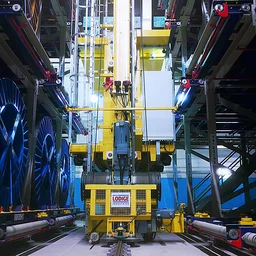

Lödige Industries has delivered a tailored automated storage and retrieval system (ASRS) incorporating an elevating transfer vehicle (ETV) to handle cable drums and transformers. The four‑level system maximises the use of the existing 800 m² storage footprint and enhances staff safety while providing real‑time visibility of inventory. Completed in late 2023, the installation enables HK Electric to manage up to 293 storage positions efficiently, laying the groundwork for future scalability.

Project Details

Founded in 1890, HK Electric powers homes and businesses across Hong Kong and Lamma islands with one of the world’s most dependable electricity supplies, consistently maintaining service reliability above 99.999 percent since 1997.

With a commitment to innovation, safety, and operational excellence, the company continually invests in technologies that ensure both continuity and efficiency in its energy infrastructure. The new automated cable drum warehouse exemplifies this modernisation strategy.