One Partner. One System. One Flow.

Integrated handling equipment for seamless cargo processes – from landside to airside.

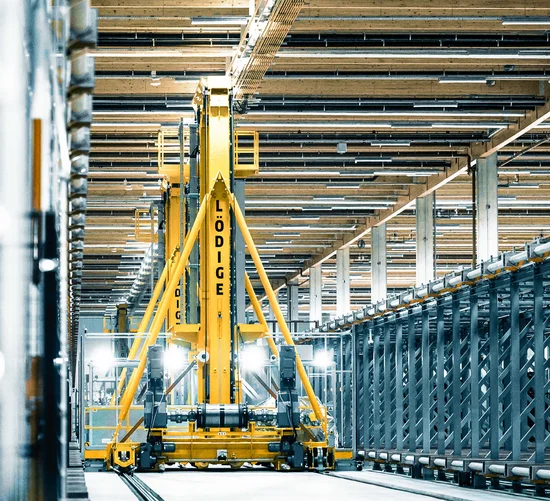

Lödige Industries provides the complete range of air cargo equipment required to move, store and handle ULDs and consignments efficiently within a terminal. From roller decks and workstations to hoists, cranes and automated transport systems, all components are engineered for reliability, safety and seamless process integration.

As a one-stop shop, Lödige combines in-house planning, design, manufacturing, installation and service. This ensures consistent quality, smooth interfaces and reliable performance across all process areas – fully integrated with digital control and monitoring through the Cargo Professional Suite, if desired.

Whether for manual zones, semi-automated material flow or fully automated cargo systems, Lödige delivers process-oriented solutions that grow with your terminal.

Benefits of Lödige's Air Cargo Handling Equipment

Engineering Excellence

Lödige cargo handling equipment is designed for continuous use in demanding air cargo environments. Our systems combine mechanical strength with precise control and advanced safety features – proven in daily operation across global hubs.

At the same time, each component is engineered with sustainability in mind: energy-efficient drives, long service life and recyclable materials minimise environmental impact and operating costs throughout the equipment lifecycle.

- Proven Engineering: Decades of expertise in air cargo logistics

- Optimised for Efficiency: High throughput, low energy use

- Safe by Design: IATA-compliant and ergonomically designed

- Flexible Integration: Modular structure for all layouts

- Future-Proof: Automation and IT-ready

- Sustainable by Design: Low energy consumption and durable materials for long-term efficiency

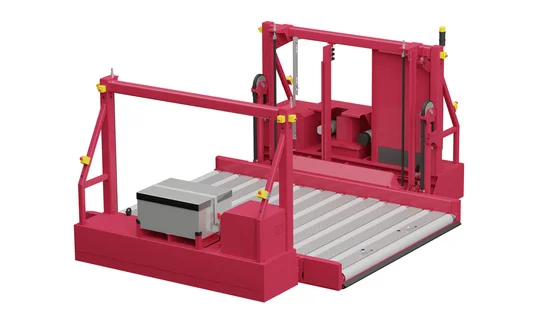

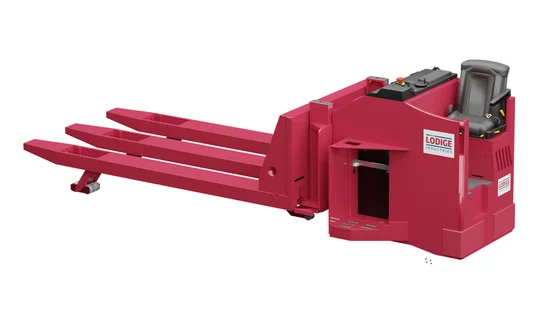

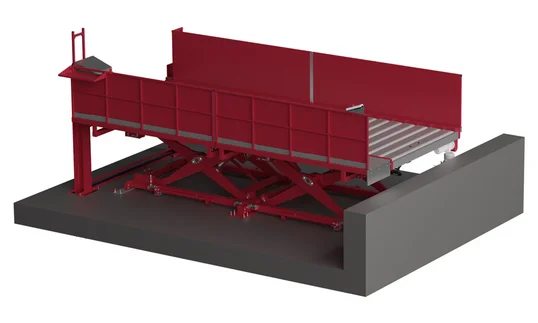

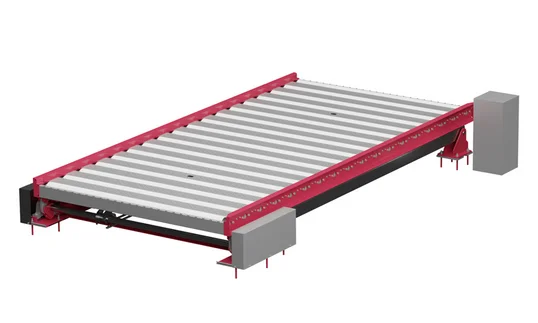

ULD Handling Equipment

Precision and Strength for ULD Movements

Our ULD handling systems ensure smooth, safe and IATA-compliant transfer of Unit Load Devices throughout the terminal. From build & break areas to automated storage and airside transfer, each component is engineered for reliability, durability and seamless system integration.

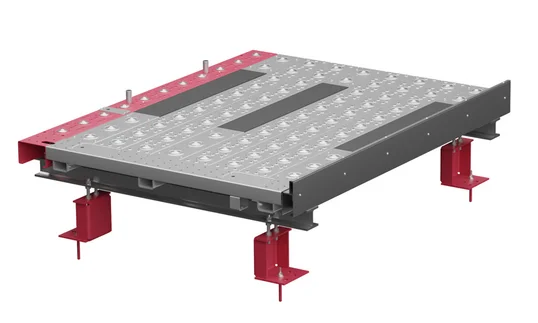

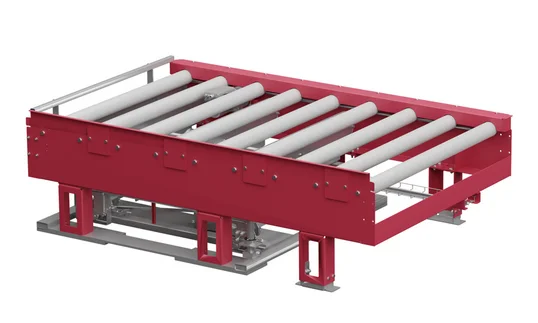

Consignment Handling Equipment

Efficient Solutions for Pallet and Piece Handling

Lödige’s consignment handling systems are designed for the fast, safe and ergonomic movement of pallets, boxes and irregular cargo within the terminal. Modular conveyor lines, lifting systems and storage solutions support smooth workflows, precise control and full visibility for all cargo types.

From Equipment to Complete Cargo Flows

Explore the Key Processes

Every piece of Lödige equipment is part of a larger system – designed to fit seamlessly into your cargo handling process. Discover how our solutions support each core area of your terminal – from landside acceptance to build & break, storage and airside interface.

Looking for the right equipment setup for your terminal?

Our experts will help you plan, adapt and scale your systems for efficient, reliable and future-proof cargo handling.

Frequently Asked Questions (FAQs)

Lödige offers complete handling systems for ULDs and consignments, including roller decks, workstations, hoists, storage systems and transfer vehicles – scalable from manual to fully automated operation

Yes. All components are designed according to IATA AHM and ULD Care standards for safe and standardised handling.

Yes. Modular design allows easy expansion or automation upgrades as terminal needs grow.

Yes – via the Cargo Professional Suite, terminals can monitor performance, manage jobs and optimise equipment utilisation in real time.

Energy-efficient drives, durable materials and lifecycle-focused design ensure long-term sustainability and reduced operating costs.