Build & Break

Efficient ULD Handling at the Core of Your Terminal

The build & break process is at the heart of every air cargo terminal. Here, shipments are consolidated into ULDs for export or broken down for import and onward distribution. Reliable, well-structured processes ensure that cargo moves on time, in full compliance and with minimal errors. Whether manual or fully automated, Lödige solutions enable safe handling, optimal staff utilisation, and full process transparency.

Typical Build & Break Workflow

Export shipments are built up at workstations with weighing and registration where required, while import ULDs are broken down based on AWB data and handling rules. Each step can be manual, semi-automated or supported by software, ensuring safe and traceable flows.

In the Build & Break process, we combine four core strengths: products, software, system planning and service. Together, they ensure safe, efficient and IATA-compliant handling – from ergonomic manual workstations to fully automated cargo flows.

Benefits of Lödige's Build & Break Solutions

Focused on operational workflows, our process solutions create tangible benefits by streamlining handling steps, reducing turnaround times and enabling smooth coordination across all air cargo terminal areas.

Automation Level

From manual workstations to system-guided handling

While transport between process zones can be automated, the physical build-up and break-down of ULDs require human execution. This process could be supported by software-controlled job distribution, scanning and tracking – ensuring transparency, accuracy and coordination across all automation levels.

Fully automated

Fully automated systems ensure maximum throughput and process reliability – even during peak times or staff shortages. They are used in high-volume terminals with strict performance targets and space constraints. The Cargo Professional Suite plans and triggers all jobs, manages equipment and ensures SLA compliance. The physical build-up and break-down of ULDs remains the task of terminal staff, guided step by step by the system.

Typical Equipment | Software Components |

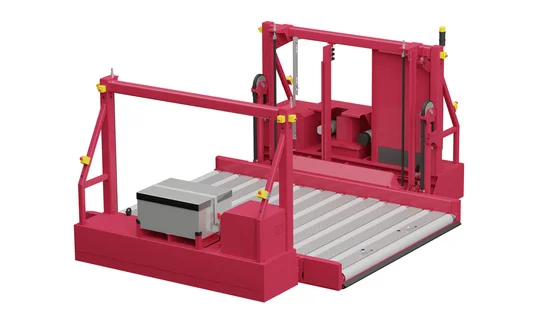

| Elevating Workstation (EWS) • For workstation connection: AGV, Transfer Vehicle, Elevating Transfer Vehicle, Roller decks • Continuous contour checker of ULD • ULD volume analyser, final contour checker and weight scales | Cargo Professional Suite (TMS) • Auto break-down |

Semi-automated and mobile

Semi-automated systems reduce physical strain, improve ergonomics, and streamline cargo flows. They are ideal for terminals that want to boost performance without moving to full automation. Functions include ergonomical build-up and break-down, as well as consignment provision on in-house pallets by guided forklifts. Job planning and task triggering are handled by the system, while execution is carried out by personnel with system support.

Typical Equipment | Software Components |

|---|---|

| • Elevating Workstation | Cargo Professional Suite (TMS) with Cargo Control and Cargo Direct Modules/ Functions: • Build / Break job execution • Build-up planning • Forklift Guidance System |

Manual & Operator-Driven Systems

Manual systems require no automation infrastructure and are ideal for basic operations or backup zones. They offer low investment, high flexibility – and can later be upgraded step by step. Functions include manual build and break, with all tasks carried out manually – from cargo handling to transport. Job tracking may be paper-based or supported by mobile device

Typical Equipment | Software Components |

|---|---|

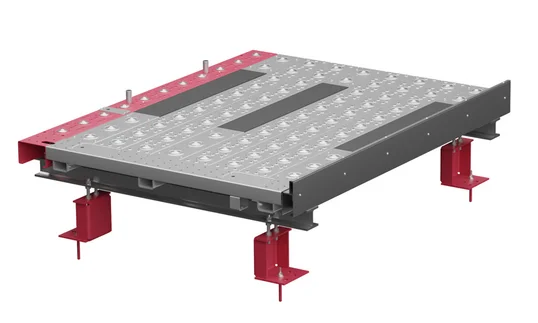

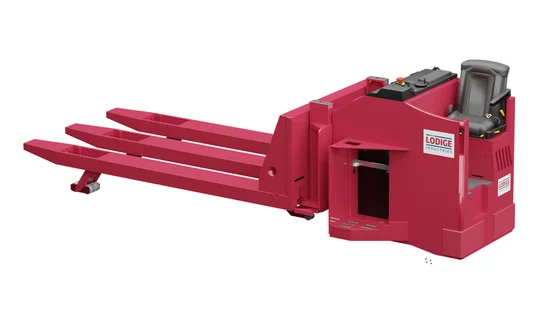

| • ULD Support Pallet • Roller Deck • Castor Deck • Ball Deck • FlexLoader and Cargo Pallet Mover for workstation connection | Cargo Professional Suite (TMS) • Auto break-down |

Discover Solutions for Build & Break

Explore products designed for safe and ergonomic ULD build-up and break-down. These solutions improve handling speed, reduce manual effort and fit seamlessly into your build & break operations.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Let’s optimise your Build & Break zone

Speak with our experts to define your optimal equipment + software setup.

FAQs

The Build & Break process refers to the consolidation (build-up) of shipments into ULDs for outbound flights and the breakdown (unloading) of ULDs after import. It is a core activity at the heart of every cargo terminal and connects landside, storage, and airside operations.

Depending on the automation level, equipment includes Castor Decks, Ball Decks, ULD Support Pallets, Elevating Workstations (EWS), Cargo Pallet Movers, and fully automated interfaces like AGVs.

Efficiency is improved by optimising workflows, reducing manual handling, and integrating flexible or automated equipment. Lödige’s modular systems enable scalable layouts with short transfer paths and ergonomic build-up areas.

Lödige's Cargo Professional Suite (terminal management system) can support all possible levels of automation in this process.

Yes. Lödige systems are modular and support phased upgrades. You can start with manual decks, add semi-automated transport later, and integrate AGVs when volumes increase.

Absolutely. All equipment and processes are fully compliant with IATA ULD Care, AHM 911, and relevant safety and operational guidelines.

EWS platforms are adjusted by pressing dedicated up and down buttons to reach the ideal working height, reducing lifting effort and the risk of injury. They are available in 10ft, 15ft, or dual 20ft configurations with integrated roller decks and safety skirts.

These mobile systems help to reduce fixed infrastructure, increase flexibility, and support quick repositioning of ULDs within the terminal. They are especially effective during peak periods or in constrained spaces.

Yes. Systems like Castor Decks, Ball Decks, and EWS are available in galvanised or stainless-steel finishes and are suitable for temperature-controlled environments.

Lödige offers three levels:

- Manual: for low-volume or flexible handling

- Semi-automated: ergonomic, mobile support systems

- Fully automated: including AGVs, ETVs, automated roller deck lines, and real-time software control

The Cargo Professional Suite provides interfaces to external Cargo Management Systems (CMS), connects with handheld scanners, and ensures real-time job allocation, inventory updates, and SLA monitoring across all operational layers.

Solutions can be scaled in terms of workstation numbers, automation level, software functionality, and layout. From small handling areas to high-throughput hubs, the system grows with your needs.